Case studies

Our case studies illustrate how we partner with clients to understand their unique challenges and provide tailored, innovative solutions. We focus on building long-term relationships, ensuring our customers benefit from our expertise throughout the entire process—from design to deployment.

The advantages of EDM for the automotive sector

The advantages of EDM for the automotive sector: The commitment by the biggest electric car manufacturer to ONA.

EDM for the manufacture of rubber and plastic injection molds

LEROY TOOL & DIE chooses ONA as its EDM supplier for the manufacture of rubber and plastic injection molds

EDM for the manufacture of molds and parts for the automotive sector

JR MOLDES reinforces its production capacity for the manufacture of molds for the automotive sector thanks ONA’s EDM technology

Automation in the manufacture of automotive sector molds with EDM

ONA’s EDM automates the manufacturing process of molds of NINGBO HELI MOULD TECHNOLOGY for car engines, making the production process more profitable

Advantages of wire-cut EDM for the machining of turbine disk firtree profiles

Advantages of incorporating wire-cut EDM for the machining of turbine disk firtree profiles for the aeronautics sector

EDM to manufacture highly accurate parts with quality finishes.

EDM to guarantee the biggest competitive advantage: manufacture of highly accurate parts with quality finishes.

EDM: excellence and sustainable production for the automotive sector

Stickel GmbH: EDM is perfect to achieve excellence and sustainability in the manufacture of parts for the automotive sector

The advantages of EDM for the manufacture of high added-value parts

Advantages of EDM for the manufacture of high added-value parts: excellent traceability guaranteeing their optimal completion

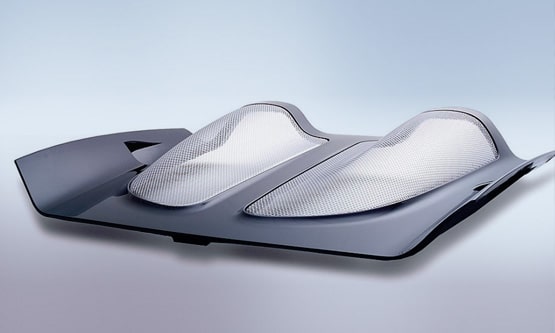

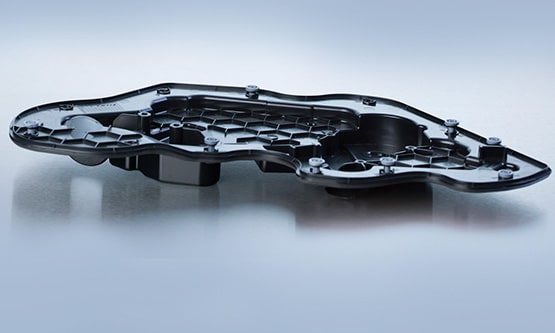

EDM for the manufacture of large molds for the automotive sector

EDM as the perfect solution for manufacturing large molds for major automotive firms as the German firm BUKUMA

Microholes EDM High level of precision for more demanding finishes.

ONA extends its range to Microholes EDM technology which enables the manufacture of the most complex pieceswith the highest precision.

Sort by subject

Last case studies

- EDM for the machining of the largest turbine disc firtrees.

- Dubral optimises the precision and quality of its cutting with ONA AV35 model

- Sermec acquires the ONA AV35 machine to strengthen its EDM machining capacity

- ONA EDM technology optimises the performance of the MCM production process

- Sabacaucho to machine large moulds for elastomeric parts with the ONA IRIS8 B1L+ machine

- Tecnijusta expands its capacity to manufacture larger moulds with the ONA Iris 6 machine

- Molde Absoluto takes a leap forward in the pursuit of excellence with the ONA IRIS6+ machine

- Innovation in the design of the ONA Halley model, the digital native machine

- AarKel achieves new levels of excellence in EDM machining with ONA.

- ONA Fast Hole Technology: the cutting-edge solution for more efficient turbines