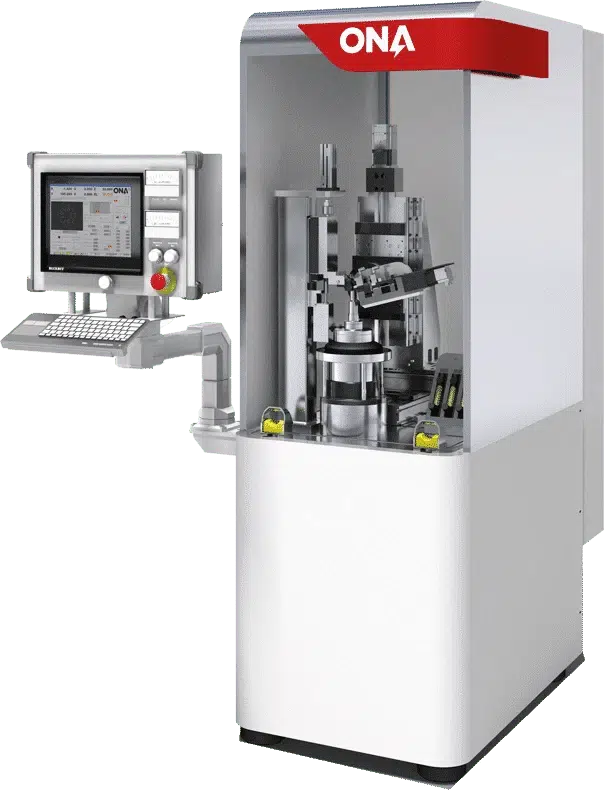

OUR MICROHOLE MACHINE

ONA incorporates in its die-sinking EDM the digital generator with the highest power in the market, an ecological filter and the possibility of including a second head to reduce erosion times.

6 reasons to choose our

microhole EDM machine

6 reasons to choose our microhole EDM machine

A complete automated solution

Our micro hole machine can be fully automated, enabling seamless, hands-free operation for high-precision perforation tasks. With advanced control systems, it ensures consistent quality and accuracy, reducing manual intervention and increasing production efficiency. This automation capability makes it ideal for industries requiring precise and repeatable micro hole applications, such as electronics, medical devices, and aerospace components.

Our microhole EDM machine has been designed and developed in collaboration with the American company AAEDM, which has been part of the ONA group since 2016. AAEDM, based in Ann Arbour, Michigan, has more than 50 years of experience in the development of solutions for the manufacture of injectors.

What do you

need to create today?

Strategic Role of EDM and Additive Manufacturing in Defense Advanced Manufacturing

Discover how EDM and additive manufacturing are transforming defense, boosting operational resilience, self-sufficiency, and precision in military production.

ONA IRIS-08B1L+ with 200-amp generator boosts productivity at Schlumberger

Schlumberger boosts its productivity with the new ONA IRIS-08B1L+ equipped with a 200 amp generator

EDM for the machining of the largest turbine disc firtrees.

ONA’s WEDM technology has proven to be a match for conventional methods such as broaching and milling in terms of quality and precision

Dubral optimises the precision and quality of its cutting with ONA AV35 model

The acquisition of the ONA AV35 model has allowed the company to improve the precision in its cutting, increasing efficiency

Sermec acquires the ONA AV35 machine to strengthen its EDM machining capacity

This fleet currently includes 4 wire EDM machines (AF25, AF35, AV25 and AV35), as well as a DR2 model erosion drilling machine.

ONA EDM technology optimises the performance of the MCM production process

The acquisition of ONA’s AV25, AV35 and AV60 models has meant an increase in profitability and quality for MCM and a high level of satisfaction.