4 reasons to choose of EDM for your automotive parts

Discover Concours Mold ’s case study!

1

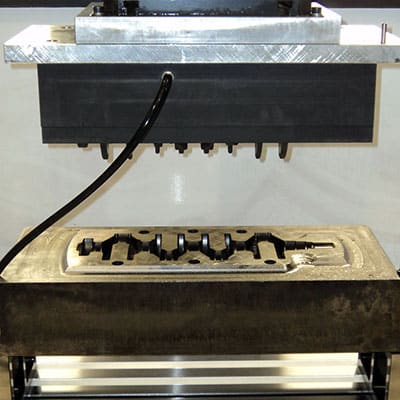

LESS PARTS

Reduces the number of parts necessary to manufacture the bodies of the cars.

2

LESS COSTS

Reduces operation costs, manufacturing costs, factory size and, consequently, its operating costs.

3

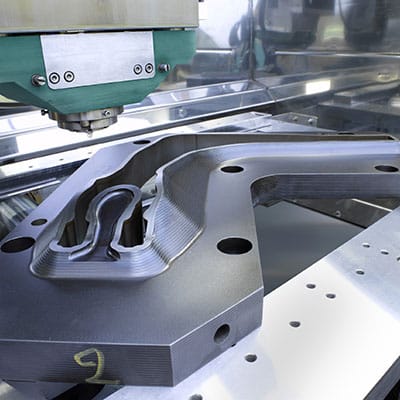

Maximum Flexibility

Unprecedented flexibility to adapt each unit to each customer’s individual needs thanks to its modular design.

4

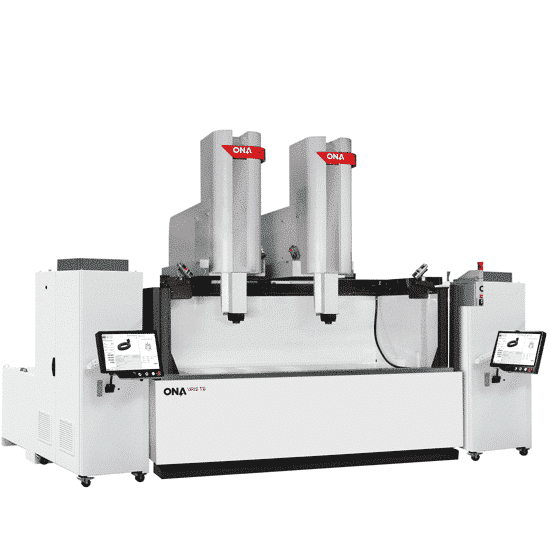

LESS TIME

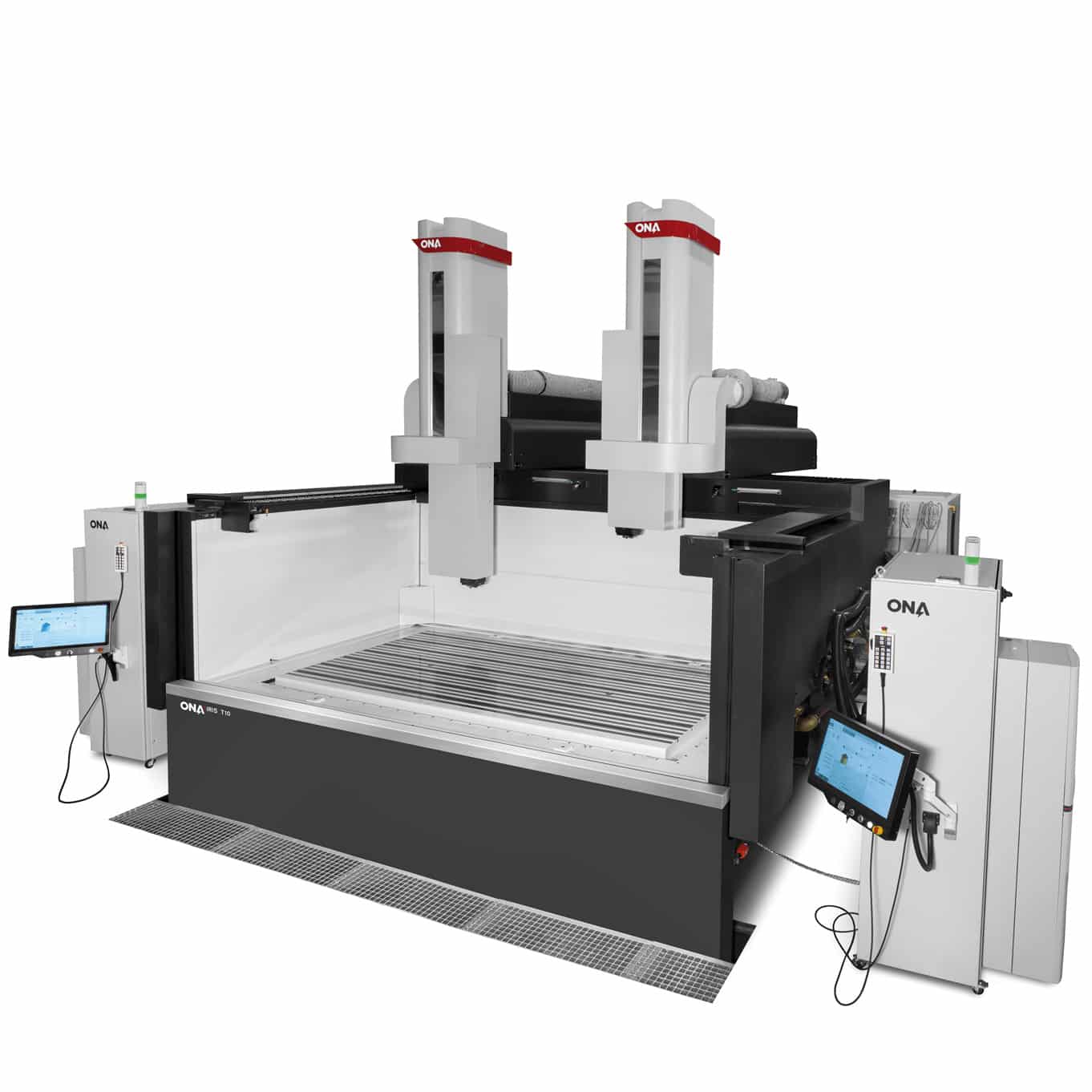

Reduces production time in half incorporating a dual head into the machine, like the one in our IRIST10 model.

VIDEO

\ VIDEO

\ MAIN APPLICATIONS

\ MAIN APPLICATIONS

CASE STUDIES

AarKel achieves new levels of excellence in EDM machining with ONA.

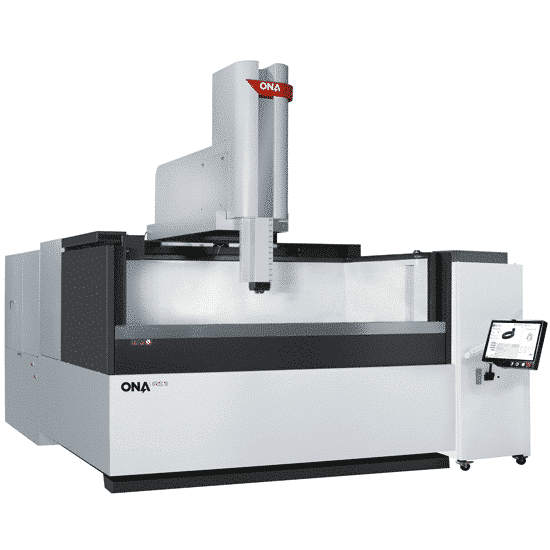

AarKel has succeeded in standing out in EDM machining thanks to the collaboration with ONA with the installation of ONA QX8 and ONA IRIS T10 C2 models.

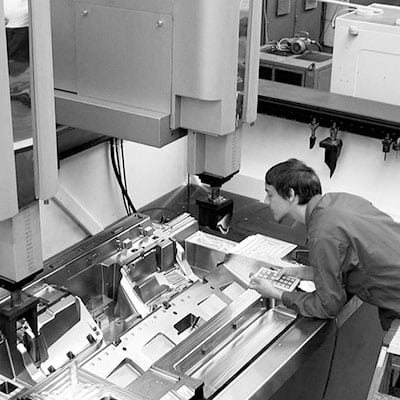

The advantages of EDM for the automotive sector

The advantages of EDM for the automotive sector: The commitment by the biggest electric car manufacturer to ONA.