ONA’s EDM automates the manufacturing process of molds of NINGBO HELI MOULD TECHNOLOGY for car engines in automotive sector, making the production process more profitable

\ Automation in the manufacture of automotive sector molds with EDM

NINGBO HELI MOULD TECHNOLOGY is the largest manufacturer of moulds for automobile engines in China. It bases its business philosophy on innovation and customer proximity. And it was these two features that led the company to confide in ONA as a supplier of EDM machines. Its equipment includes two EDM QX7 die-sink machines and a 90-position Erowa robot.

HELI MOULD was founded in 1980 to manufacture moulds, particularly for the automotive industry. Located in Ningbo, a modern international port city, the Chinese company has always been strongly committed to innovation, research and development of casting dies, making it one of the country’s key high-tech firms in the steel casting industry. It boasts an AAA enterprise credit rating from the China Die & Mould Industry Association.

Heli Mould specialises in manufacturing dies for the auto industry. It manufactures automobile engine cylinder block moulds, engine cylinder head moulds, transmission case moulds, impact beams, bumpers, automotive flywheel housings and rail transit gearbox housings.

Working with a sector as demanding as the automotive industry it is essential to have the best suppliers. Heli Mould’s search for the best EDM supplier brought it to ONA and an assurance of improvement in its production processes. Seeking to provide optimal service to its customers, the Chinese firm were drawn by ONA‘s quality and no-nonsense approach.

ONA die-sink machines (Heli Mould has two QX7 models) ensure savings on electrodes in the manufacturing processes. This means that the firm can produce more moulds with fewer electrodes. Moreover, the manufacturing process is fully automated, removing the need to change electrodes and thus preventing any loss in production time. All this means more moulds in less time—and, thus, more cost-effective production.

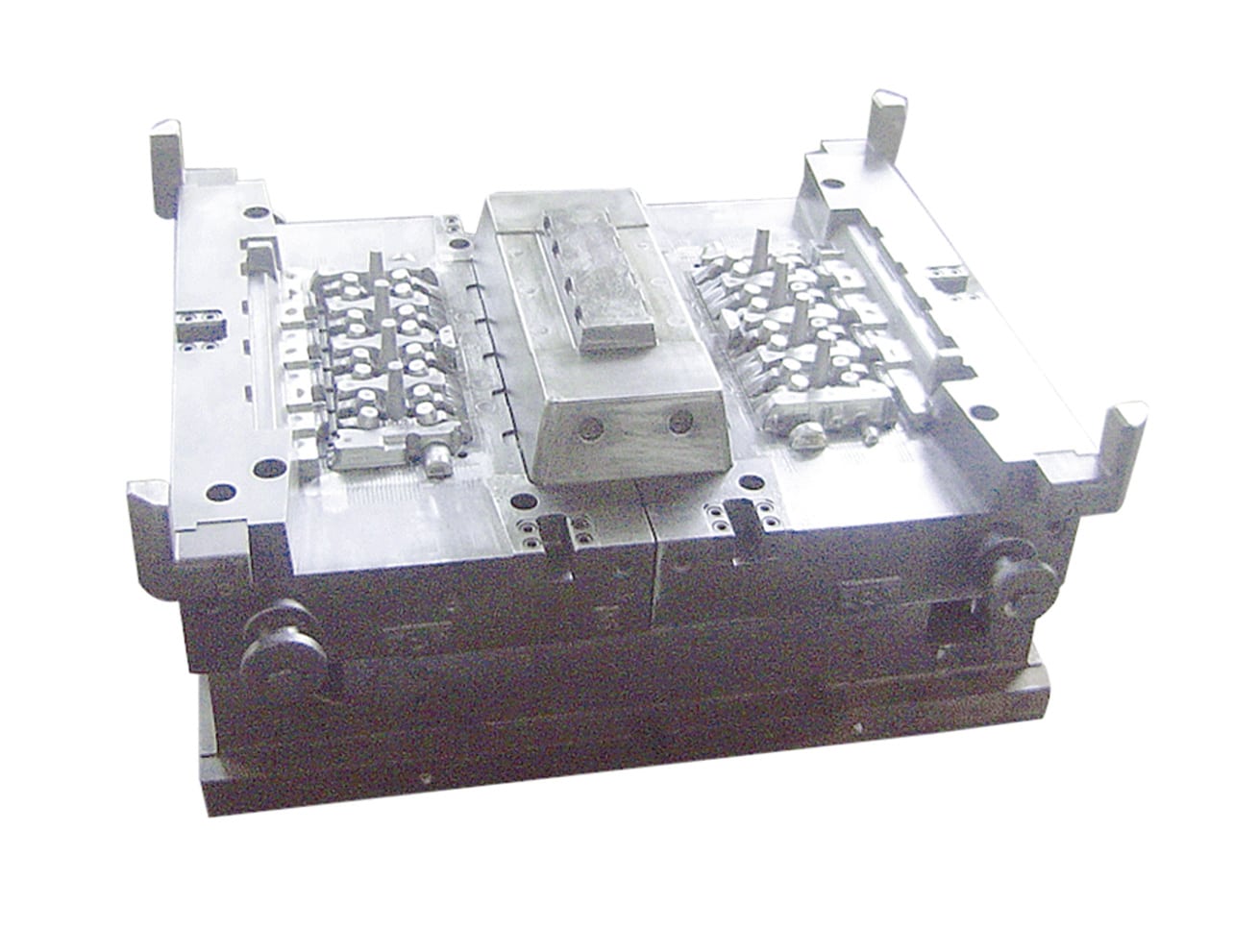

Plastic injection mold made by EDM.

ONA QX7 and its many advantages

Among the many advantages that the ONA QX7 EDM machines offer for Heli Mould ‘s production processes are:

- Savings in electrodes due to reduced wear. The new smart generator incorporated in these models optimises the EDM process and adapts to discharge conditions at any given time, resulting in improved productivity

- The new QX generator is 100% digital, configurable and programmable.

- 40% increase in speed for machining wedges. Wedges made in less time, with fewer electrodes.

- Automation of the two ONA QX7 machines with an 80-position robot. This means that the machine can operate for up to 6,500 hours per year, increasing available production time. In addition, machine stoppage time has been reduced.

| ACTIVITY | Leader in die casting in China: Large scale die casting, low-pressure casting moulds, gravity casting moulds, various lines of moulds, hot and cold box moulds (casing), R&D in thermoforming stamping dies. |

| WORKFORCE | 738 employees. |

| EQUIPMENT | Two QX7 machines and an 80-position Erowa robot |

| SPECIALITY | Manufactures different types of large mould. |

| CLIENT SECTORS | Largest manufacturer of moulds for auto engines in China |