We are EDM

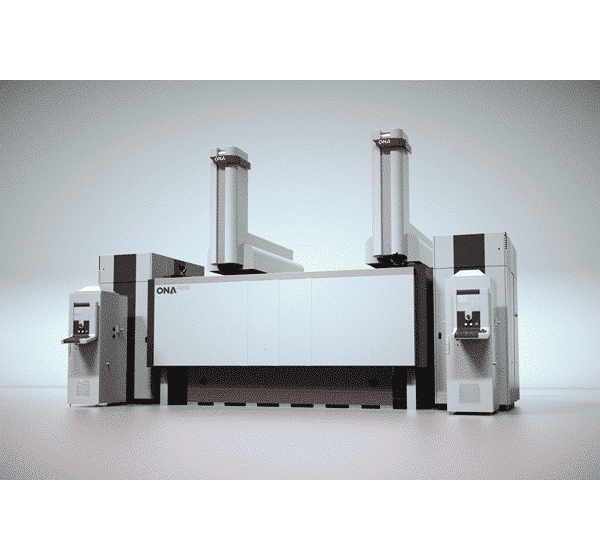

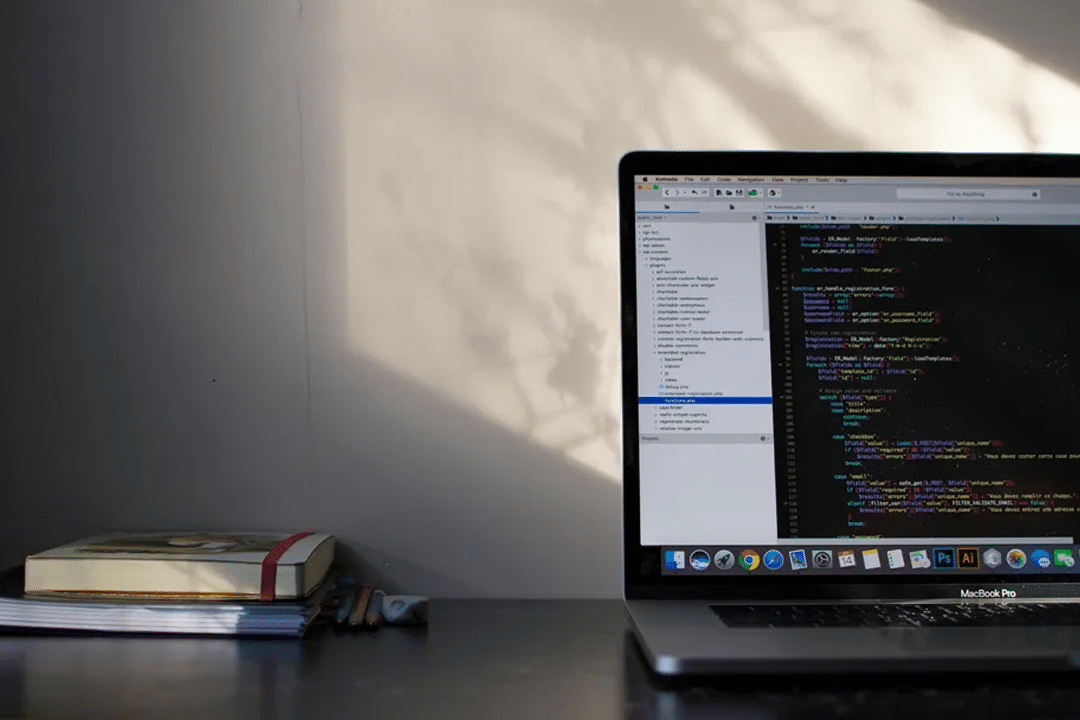

ONA EDM: We are the world’s most specialised EDM manufacturer

ONA EDM: We are the world’s most specialised EDM manufacturer

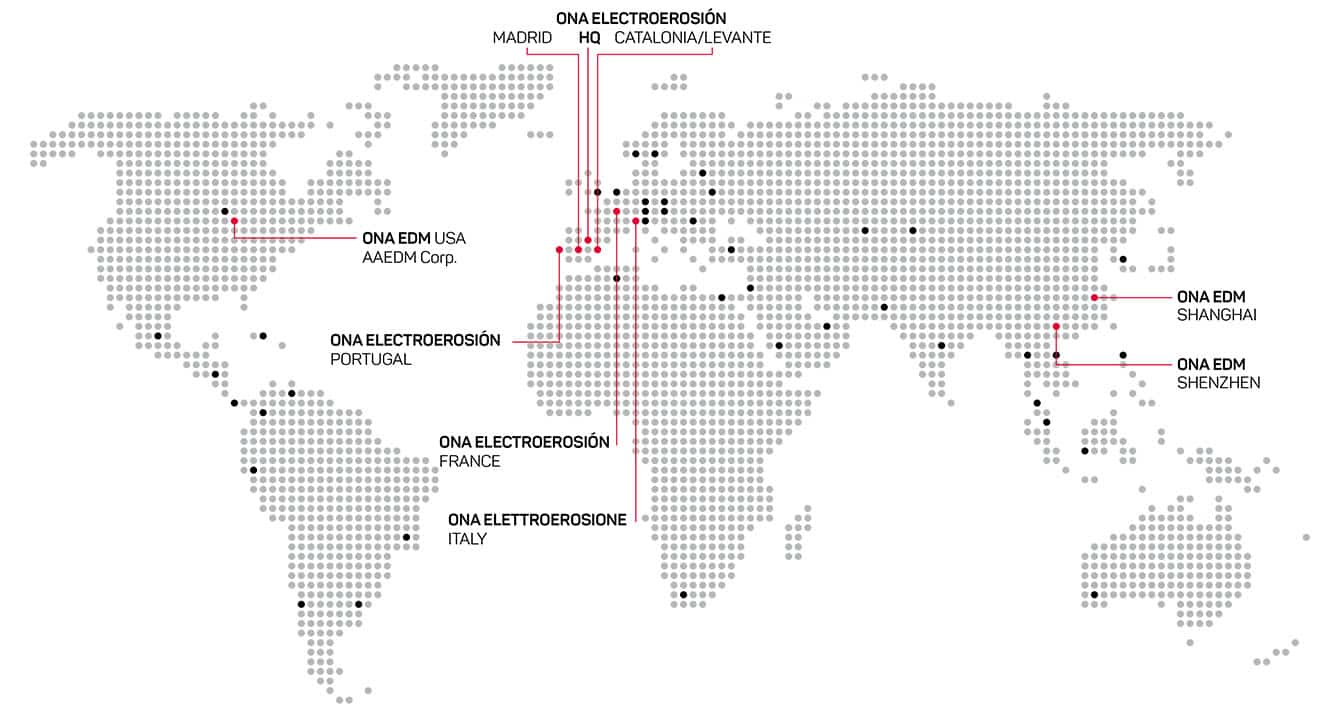

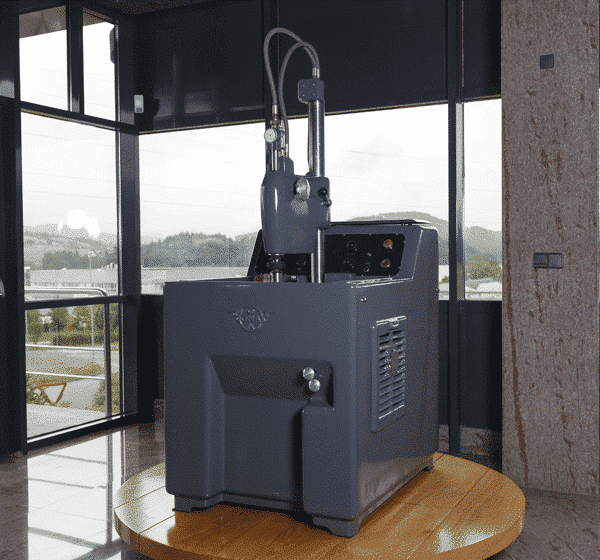

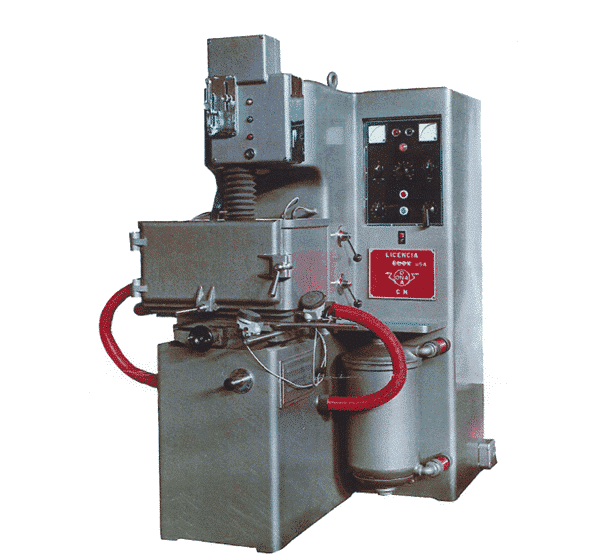

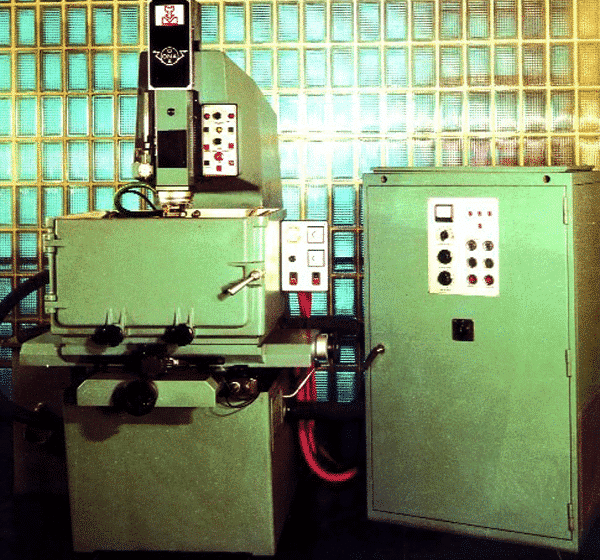

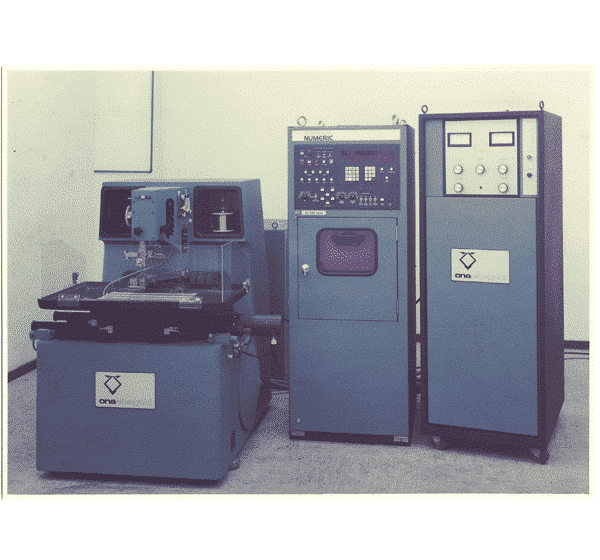

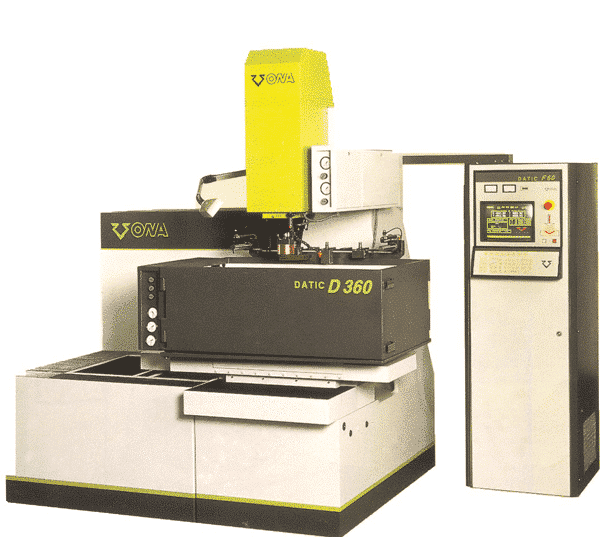

At ONA we are pioneers in EDM technology. Our over 70 years of history have made us the most specialised manufacturer in the world.

We guarantee our clients’ competitiveness and build long-term partnerships.

In our commitment to a personalised service, we accompany the client throughout the entire process of acquisition and deployment of each piece of equipment in any place in the world.

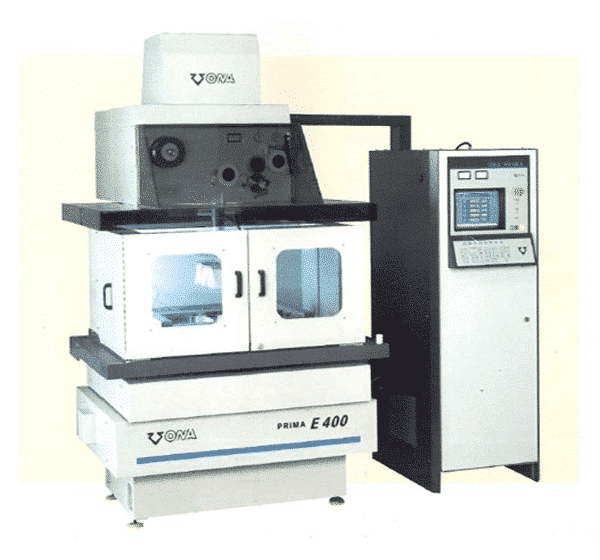

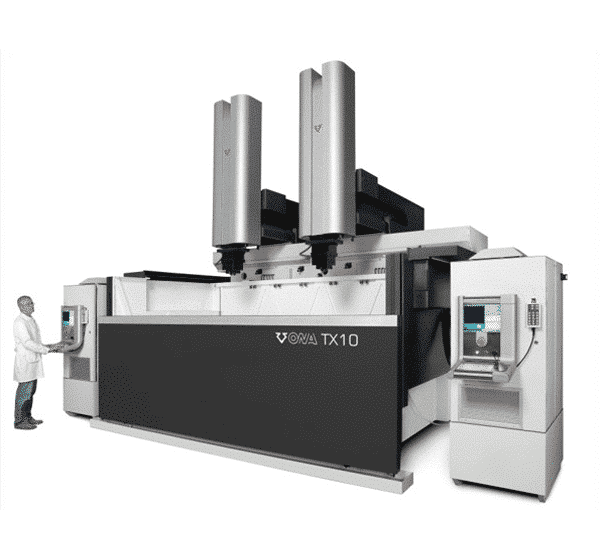

We design and create customer-specific solutions in order to be able to deliver the perfect solution.

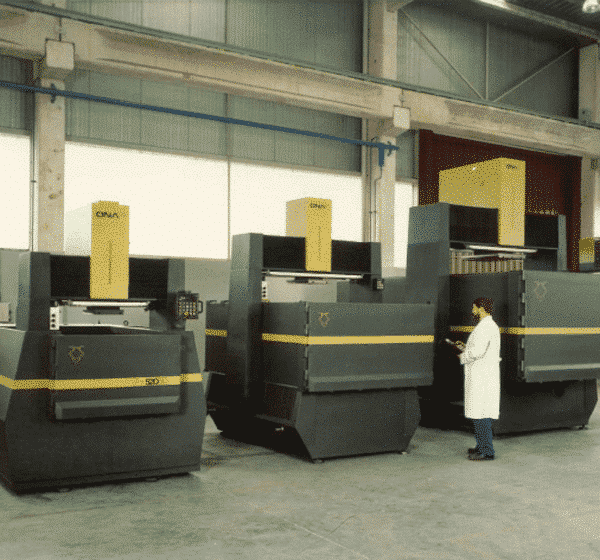

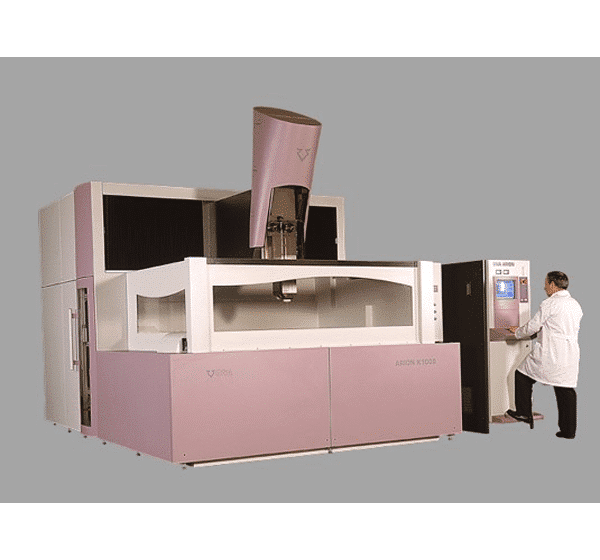

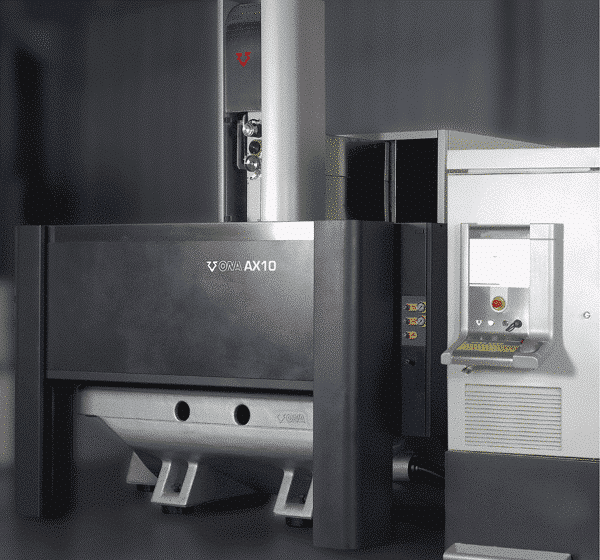

We are world leaders in the manufacture of large machines and experts in special solutions.

In line with this personalized approach, we create automation solutions, and work on projects to deliver turnkey solutions.

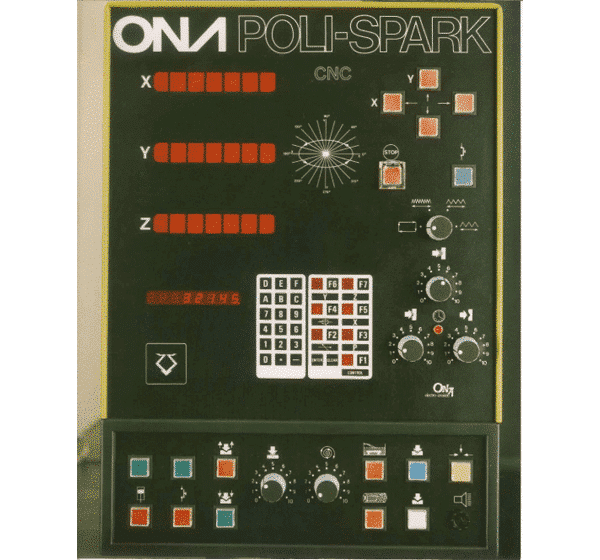

We include the latest developments in Industry 4.0. and digitalization in all our equipment.

98%

overall equipment

effectiveness (OEE)

overall equipment effectiveness (OEE)

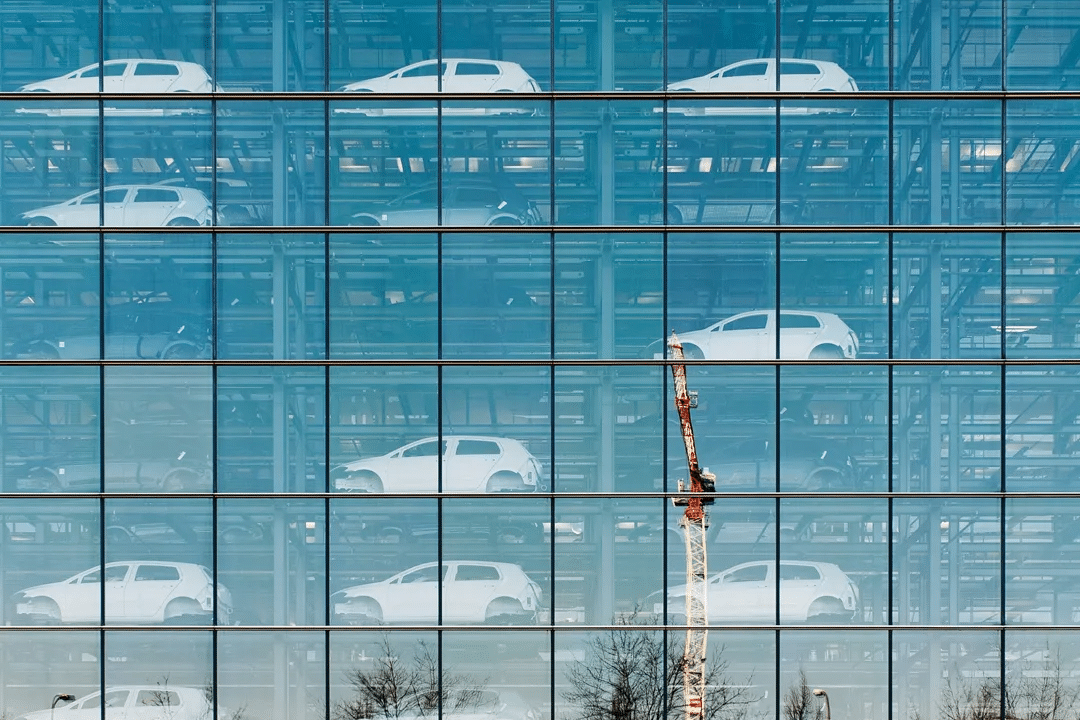

60

countries of 5 continents

with ONA machines

countries of 5 continents with ONA machines

15.000

machines installed all

over the world

machines installed all over the world

70

large machine

configurations

large machine configurations

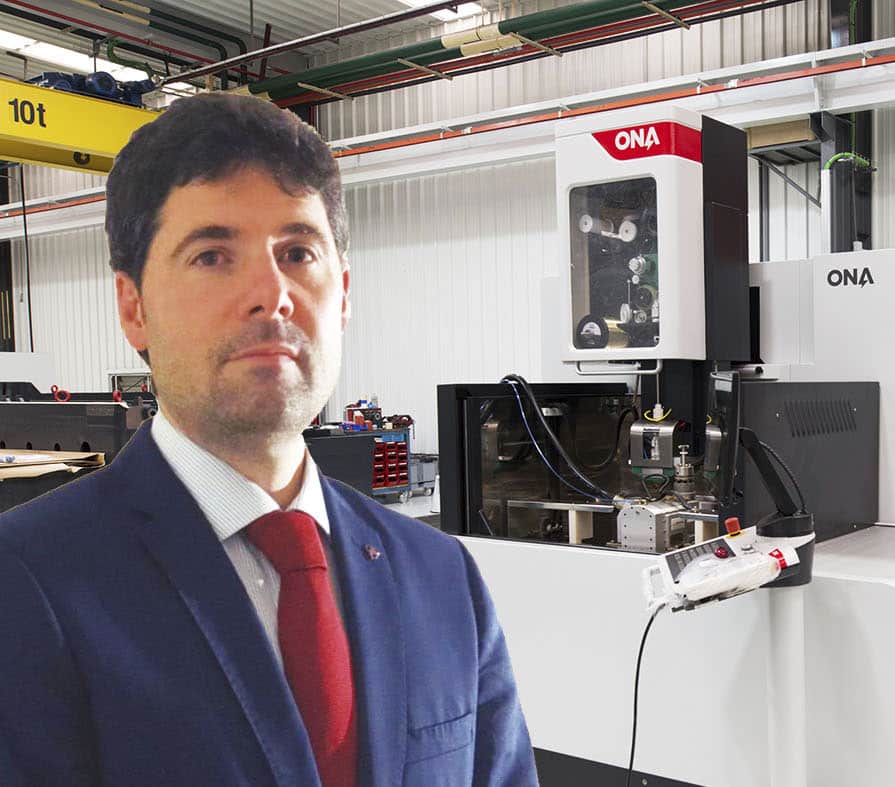

PEOPLE

An expert team of specialists focused on your needs. Working hand in hand, with the diligence and flexibility you require and with the expertise and precision that more than 65 years in the world of EDM give us.

ONA is human capacity.

“We’ve built up a relationship of trust with ONA. What we most value is their approachability and their capacity to listen. ONA is a solutions provider with very similar values to our own”

Yannick Suzanne, head of S.A. HOURAT (France)

“We’ve built up a relationship of trust with ONA. What we most value is their approachability and their capacity to listen. ONA is a solutions provider with very similar values to our own”

Yannick Suzanne, head of S.A. HOURAT (France)

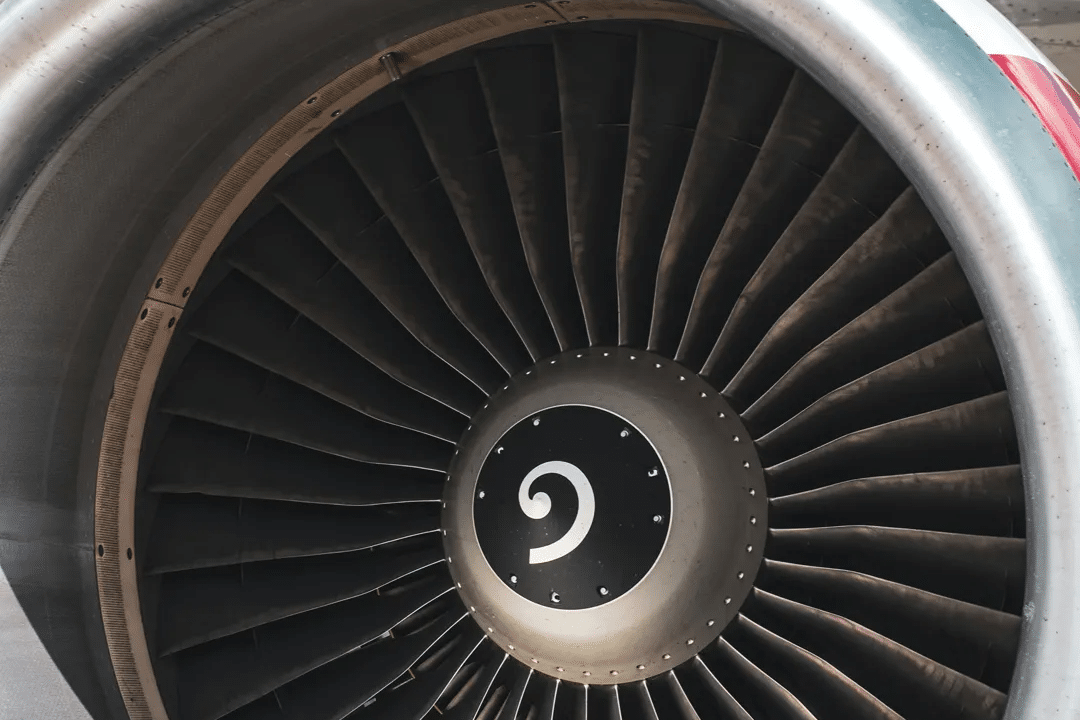

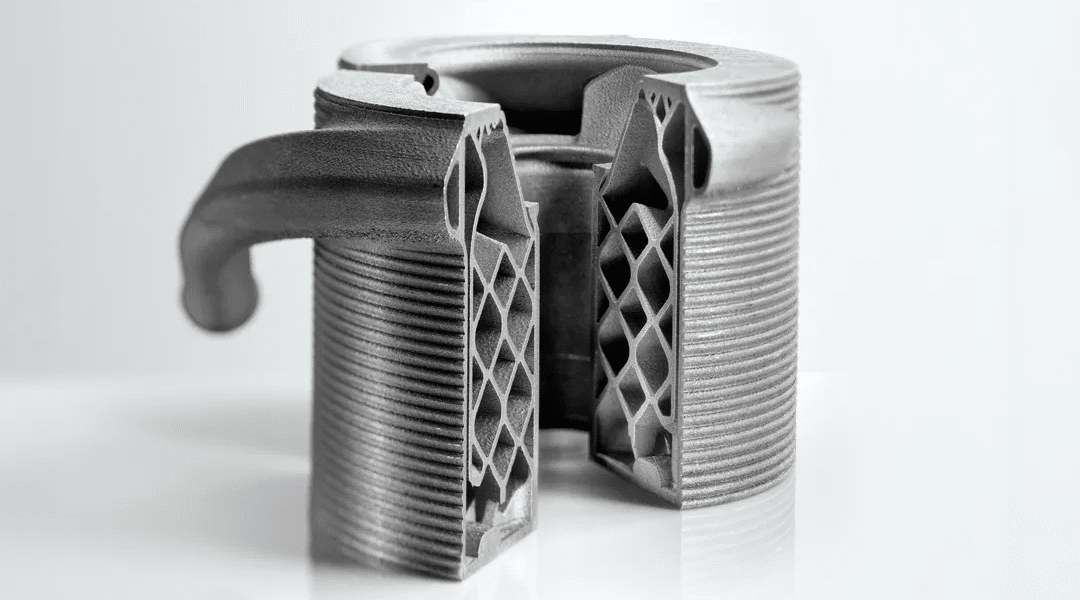

TECHNOLOGY

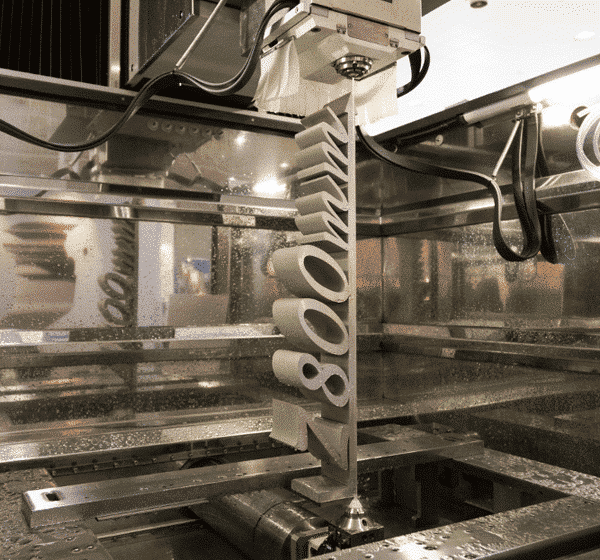

Everything that comes with being pioneers in EDM, more than 65 years of experience and our commitment to developing our own technology, have enabled us to always provide you with the perfect and most profitable solution for your project. Our secret: combining the expertise of our two key departments; applications and R&D&i.

ONA is technological capability.

DEPARTMENT OF R&D&I

This is the department in charge of solving the challenges, tests and doubts our customers bring to us.

This is the best way to be in continuous contact with both the customer’s needs and the market’s requirements. The Department of Applications is the company’s technical nexus with the exterior, enabling us to be up to date with what’s going on in the industrial sector. A team formed by 7 technicians with more than 100 years of combined experience in EDM that exemplifies ONA’s skill.

DEPARTMENT OF APPLICATIONS

Research is key for the continuous improvement of our products. Our R&D&I department is focused on the development of our own technology, with the aim of increasing the capacity of our machines, improving their functionalities and anticipating our customers’ needs. We also collaborate with different Technological Research Centres and Universities around the world (ILT-Frauhofer and WZL-Aachen in Germany and Tekniker, Tecnalia, Ideko, Higher Technical School of Engineers in Bilbao, Spain), and participate in European Research and Development projects (PROSECO, SAPHIRE). A team formed by 25 people; multidisciplinary, responsive and with initiative, representing ONA’s knowledge.

“The great complexity of our moulds called for cutting-edge EDM technology to meet our highly stringent requirements”

Managing Director of Bukuma Mirko Schnur (Germany)

“The great complexity of our moulds called for cutting-edge EDM technology to meet our highly stringent requirements”

Managing Director of Bukuma Mirko Schnur (Germany)

PROFITABILITY

PROFITABILITY

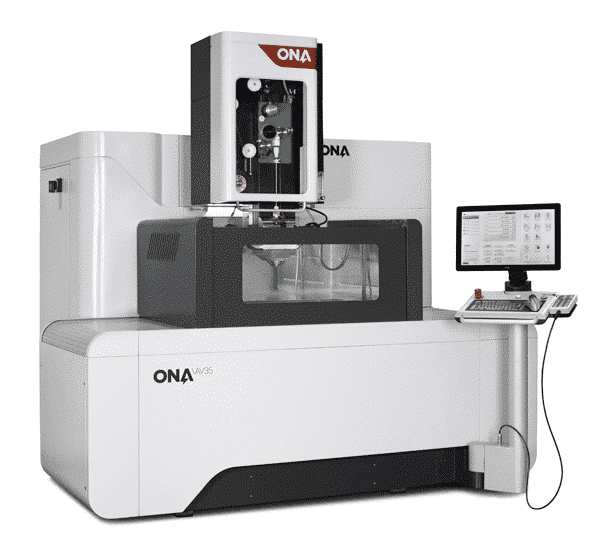

Yes, we give you the solution you need, but we strive to also make it the most profitable solution. Your success and long-term profitability is the cornerstone of each one of our proposals; offering you the most reliable solution with the highest profitability.

ONA optimises your investment.

PRODUCTIVITY IN ROUGHING OPERATIONS

PRODUCTIVITY IN ROUGHING OPERATIONS

PRODUCTIVITY IN FINISHING OPERATIONS

PRODUCTIVITY IN FINISHING OPERATIONS

WEAR OF ELECTRODES

WEAR OF ELECTRODES

INCREASED PROFITABILITY THROUGH SAVINGS IN ELECTRODES

This is the department in charge of solving the challenges, tests and doubts our customers bring to us.

This is the best way to be in continuous contact with both the customer’s needs and the market’s requirements. The Department of Applications is the company’s technical nexus with the exterior, enabling us to be up to date with what’s going on in the industrial sector. A team formed by 7 technicians with more than 100 years of combined experience in EDM that exemplifies ONA’s skill.

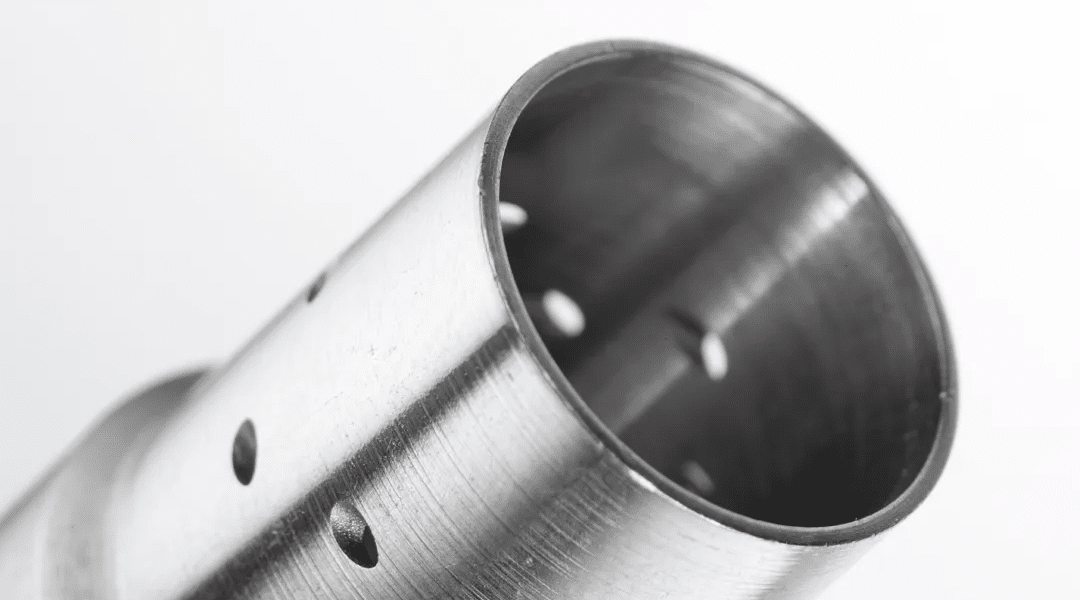

EUROPEAN TECHNOLOGY

GUARANTEEING MAXIMUM RELIABILITY

EUROPEAN TECHNOLOGY

GUARANTEEING MAXIMUM RELIABILITY

Keeping with our commitment to quality, we manufacture our machines in their entirety in Europe with top-of-the-line components.

ONA GROUP