Case studies

Our case studies illustrate how we partner with clients to understand their unique challenges and provide tailored, innovative solutions. We focus on building long-term relationships, ensuring our customers benefit from our expertise throughout the entire process—from design to deployment.

MAIER trusts on ONA NX6 EDM model for the manufacture of large molds

MAIER increases its EDM capabilities with the acquisition a new ONA NX6 die-sinking EDM model for increasing the production of large molds.

ONA implements EDM machines for Volkswagen Autoeuropa

Volkswagen Autoeuropa purchases two ONA EDM machines: ONA AV35 and ONA QX4 for its press and part stamping area

EDM for the manufacture of trimming dies at PSA Peugeot Citroën

PSA Peugeot Citroën in his plant in Mulhouse has nine wire EDM machines of ONA for the manufacture of trimming dies

Custom wire-cut EDM machine with specific needs for cutting gas turbine rings

Custom solution with specific needs to NELIDOV: Flexibility and customisation of a wire-cut EDM machine for cutting gas turbine rings

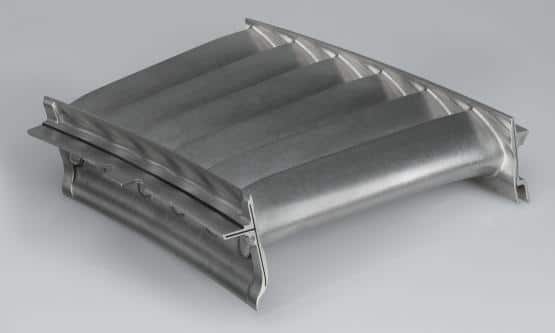

EDM for the erosion of honeycomb structures in aircraft engines.

HAESL, a joint venture between Rolls-Royce, SIAEC and HAECO, uses ONA EDM machines for the erosion of honeycomb lining structures used in aircraft engine components.

MAIER uses EDM for the manufacture of plastic injection moulds for cars

MAIER uses ONA EDM for the manufacture of plastic injection moulds of the front exterior car grille for automotive components.

EDM for the manufacture of strip seal slots in NGV segments

ITP trusts on the power of 12 die sinking ONA EDM machines for the erosion of the strip seal slots in the NGV segments of low pressure turbines (LPT)

Advantages of the ONA TQX10 twin head EDM model: productivity and quality

Concours Mold acquires an ONA TQX10 twin head EDM machine: 2 multielectrode robots and process control software for improve productivity and quality

Haier incorporates the ONA QX6+ EDM machine with microfine generator

HAIER incorporates the ONA QX6+ die-sinking EDM machine equipped with a microfine generator, filtering unit and CNC control.

EDM for manufacturing nitrided forging dies at PSA Peugeot Citroën

PSA Peugeot Citroën in Mulhouse has 9 ONA EDM machines for the manufacture of nitrided forging dies - one of the toughest tasks that Peugeot undertakes.

Sort by subject

Last case studies

- EDM for the machining of the largest turbine disc firtrees.

- Dubral optimises the precision and quality of its cutting with ONA AV35 model

- Sermec acquires the ONA AV35 machine to strengthen its EDM machining capacity

- ONA EDM technology optimises the performance of the MCM production process

- Sabacaucho to machine large moulds for elastomeric parts with the ONA IRIS8 B1L+ machine

- Tecnijusta expands its capacity to manufacture larger moulds with the ONA Iris 6 machine

- Molde Absoluto takes a leap forward in the pursuit of excellence with the ONA IRIS6+ machine

- Innovation in the design of the ONA Halley model, the digital native machine

- AarKel achieves new levels of excellence in EDM machining with ONA.

- ONA Fast Hole Technology: the cutting-edge solution for more efficient turbines