EDM as the perfect solution for manufacturing large molds for major automotive firms as the German firm BUKUMA

EDM for the manufacture of large molds for the automotive sector

Some months ago we received a visit from the German firm BUKUMA, which was looking for a large machine with very tough performance requirements. As a result of the visit they purchased an ONA QX8, which has provided excellent results. They now have three ONA EDM machines at their 2 plants.

BUKUMA’s one of the production plan.

Passion for parts – this philosophy lies in the components manufactured by Bukuma.

BUKUMA GmbH was founded in Germany in 1963. It specialises in the design and manufacturing of molds for the injection of plastic parts for the automotive and construction industries. Its customers include many of Europe’s leading automotive firms. Volkswagen, Daimler Mercedes, Audi, Lamborghini and Porsche are just some of the names that trust BUKUMA to produce their moulds.

The stringent requirements of the automotive industry meant that the firm needed to find solutions that could produce large components to a very high degree of precision. Some months ago the ONA QX8 was installed at their facilities. The excellent results obtained with this model and the good relationship forged with ONA have led them to purchase two more machines: a NX4F die-sinking EDM model and an AV100 wire EDM model. The latter model can be seen at the ONA stand (Stand C92 in Hall 13) at the 2019 Hanover fair on 16-21 September.

Technological skill at the service of our customers

BUKUMA now has several EDM machines at its facilities, so the firm knows the relevant technology well. Managing Director Mirko Schnur explains that they were not entirely happy with the results that they had obtained from several EDM machines made by other manufacturers. The great complexity of their molds called for cutting-edge EDM technology to meet their highly stringent requirements.

This led the production management at BUKUMA to visit ONA in search of a high-performance machine. They needed a large machine that would reduce production times, ensure excellent quality and be backed by professional, proximity-based technical service.

They saw first-hand the full potential of technological development of ONA as the market leader in EDM, with its broad experience in special and large-format machines.

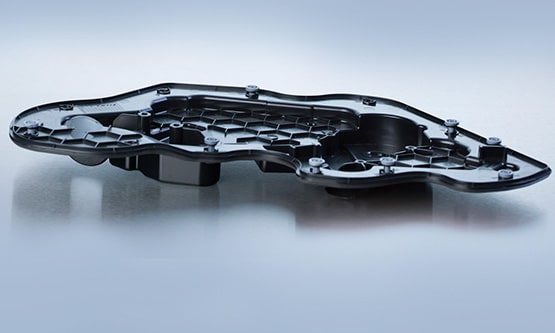

The solution offered by ONA was the ONA QX8: a large-format die-sinking EDM machine that met all their requirements.

Perfect finishes in large volumes

QX8 – DIE-SINKING EDM MACHINE

Rapid machining in large workpieces

The new machine has lived up to all their expectations. With its 2800 x 1500 x 850 mm work tank, it can handle large-sized workpieces with weights of up to 20 tons. It is also well suited to mould manufacturing, as it can work very quickly and still provide excellent surface finishes.

ONA worked closely with BUKUMA throughout the process of setting up the machine at their facilities and provided advanced training for plant operators on various applications.

The firm has chosen ONA as its partner for EDM

BUKUMA has confirmed its choice of ONA by acquiring two more machines. The ONA NX4F die-sinking EDM machine offers great performance in precision and stability, and long X and Y-axis travel. The AV100 wire EDM machine is a large-format unit that offers high machining capacity.

| EQUIPMENT | 1 die-sinking EDM machine: model ONA QX8-B1L 1 die-sinking EDM machine: model ONA NX4F 1 wire EDM machine: model ONA AV100 |

| SECTORS and customers | Mainly automotive, but also construction and medical technology. They work for leading European automotive firms: VOLKSWAGEN, DAIMLER MERCEDES, AUDI, LAMBORGHINI, PORSCHE, SEAT, etc. |

EDM for the machining of the largest turbine disc firtrees.

ONA’s WEDM technology has proven to be a match for conventional methods such as broaching and milling in terms of quality and precision

Dubral optimises the precision and quality of its cutting with ONA AV35 model

The acquisition of the ONA AV35 model has allowed the company to improve the precision in its cutting, increasing efficiency

Sermec acquires the ONA AV35 machine to strengthen its EDM machining capacity

This fleet currently includes 4 wire EDM machines (AF25, AF35, AV25 and AV35), as well as a DR2 model erosion drilling machine.

ONA EDM technology optimises the performance of the MCM production process

The acquisition of ONA’s AV25, AV35 and AV60 models has meant an increase in profitability and quality for MCM and a high level of satisfaction.

Dubral optimises the precision and quality of its cutting with ONA AV35 model v2

The acquisition of the ONA AV35 model has allowed the company to improve the precision in its cutting, increasing efficiency

Sabacaucho to machine large moulds for elastomeric parts with the ONA IRIS8 B1L+ machine

Sabacaucho’s requirement for a machine with a high capacity for machining and repairing larger moulds led the company to contact ONA.