Case studies

TURBINES

Our case studies illustrate how we partner with clients to understand their unique challenges and provide tailored, innovative solutions. We focus on building long-term relationships, ensuring our customers benefit from our expertise throughout the entire process—from design to deployment.

The machining of turbine impellers with EDM for industrial compressors

Pump and valve manufacturer trusts in ONA for the machining of turbine impellers with EDM for industrial compressors.

Custom EDM solution: Diffuser holes in turbine blades.

Custom EDM solution for a manufacturer in the aerospace and energy sector: Drilling Diffuser holes in turbine blades.

ONA AV35 wire-cut model, EDM solution for turbine disc firtree production

Gas turbine manufacturers trust in ONA AV35 wire-cut model as the perfect EDM solution for turbine disc firtree production.

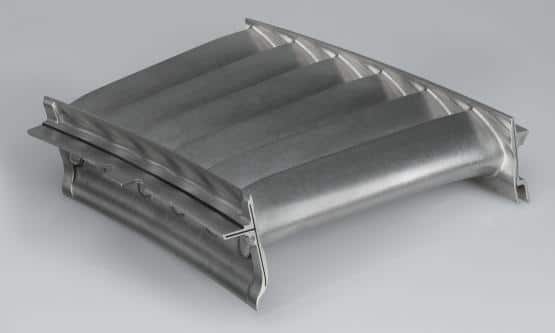

Custom wire-cut EDM machine with specific needs for cutting gas turbine rings

Custom solution with specific needs to NELIDOV: Flexibility and customisation of a wire-cut EDM machine for cutting gas turbine rings

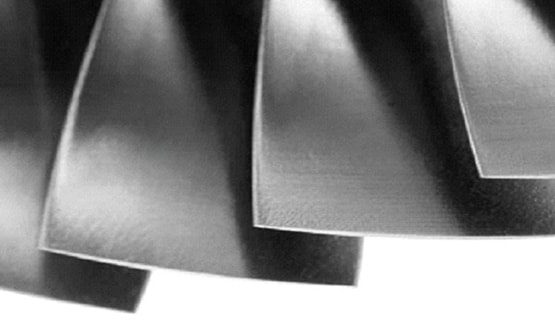

EDM for the erosion of honeycomb structures in aircraft engines.

HAESL, a joint venture between Rolls-Royce, SIAEC and HAECO, uses ONA EDM machines for the erosion of honeycomb lining structures used in aircraft engine components.

EDM for the manufacture of strip seal slots in NGV segments

ITP trusts on the power of 12 die sinking ONA EDM machines for the erosion of the strip seal slots in the NGV segments of low pressure turbines (LPT)

Sort by subject

Last case studies

- Strategic Role of EDM and Additive Manufacturing in Defense Advanced Manufacturing

- ONA IRIS-08B1L+ with 200-amp generator boosts productivity at Schlumberger

- EDM for the machining of the largest turbine disc firtrees.

- Dubral optimises the precision and quality of its cutting with ONA AV35 model

- Sermec acquires the ONA AV35 machine to strengthen its EDM machining capacity

- ONA EDM technology optimises the performance of the MCM production process

- Sabacaucho to machine large moulds for elastomeric parts with the ONA IRIS8 B1L+ machine

- Tecnijusta expands its capacity to manufacture larger moulds with the ONA Iris 6 machine

- Molde Absoluto takes a leap forward in the pursuit of excellence with the ONA IRIS6+ machine

- Innovation in the design of the ONA Halley model, the digital native machine