AD wire-cut EDM machines: profitability and precision at a low cost.

\ AD wire-cut EDM machines: profitability and precision at a low cost.

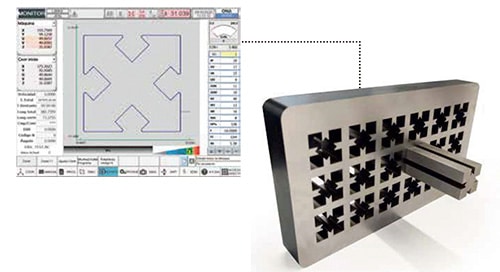

Our complete new catalogue of wire EDM units includes the AD mode, a high-production machine that will revolutionise the market: low-cost precision and profitability. The AD25 and AD35 models of ONA’s newest model have been on the market for nearly a year. Its highly competitive price point and high performance make it a smart buy for those looking to make their production processes more profitable.

\ Make production processes more profitable with the AD25 and AD35 models, guaranteeing maximum precision at a low cost.

\ There are no trade-offs. The best price and finishes together with ONA’s best assistance service.

At ONA, we continue working to develop solutions that help our customers obtain the highest degree of profitability. With the AD EDM range, our goal is to offer the best product within everyone’s reach.

That is why creating a machine that guarantees the best precision at the best price is so important to us. We did it! At ONA, we have manufactured the market’s most competitive compact wire machine. This is a great opportunity for anyone that wants to introduce EDM technology into their production processes.

Profitability and precision at a low cost.

Experts know that the main goal of EDM is to obtain the best results, keeping it as simple and affordable as possible. ONA’s AD25/35 range guarantees all these factors. Its affordable price point and high reliability manufacturing parts are complemented by its simple operations and the highly intuitive nature of all ONA’s units.

A CNC with the most advanced technology, with a Windows-style operating system and the ability to control 5 axes.

Guaranteed Reliability.

At ONA, we believe that the reliability of our parts is one of the most important aspects when it comes to designing new units. This time is no different. Our goal of providing a low-cost solution had to be entirely aligned with the demand for developing a precise model with perfect finishes. Among other benefits, the AD25 and AD35 machines offer:

-

-

- A CNC with the most advanced technology, with a Windows-style operating system and the ability to control 5 axes, 4 of them (X, Y, U, V) simultaneously.

- Its expert EDM system incorporates the ease of automated handling that guarantees the machine’s maximum performance in each work phase.

- Technological tables developed for precision cutting with total reliability. Verticality precision of 5 microns with a cut + 1 check.

- The best finish with great precision in the piece’s critical points (corners and circles) thanks to automatic control of erosion parameters and lateral unload for checks.

- An automatic wire curvature point compensation system that ensures maximum precision for pieces with conical geometries. This new mechanism makes the user’s work incredibly easier since precise conical pieces can be made entirely automatically.

- And of course, low maintenance costs and excellent performance thanks to its low energy consumption.

-

ONA in its purest form.

With the AD25 and AD35 units, there are no trade-offs. You will get the most profit out of your production processes, manufacturing at a lower cost with ONA’s guarantee and our best customer support service. Only once all our highly-demanding tests are passed, and the production process you’ve requested is verified will we proceed to install and commission the machine at your facilities. At ONA, we will be there to assist you for the long haul, when and where you need it, anywhere in the world.