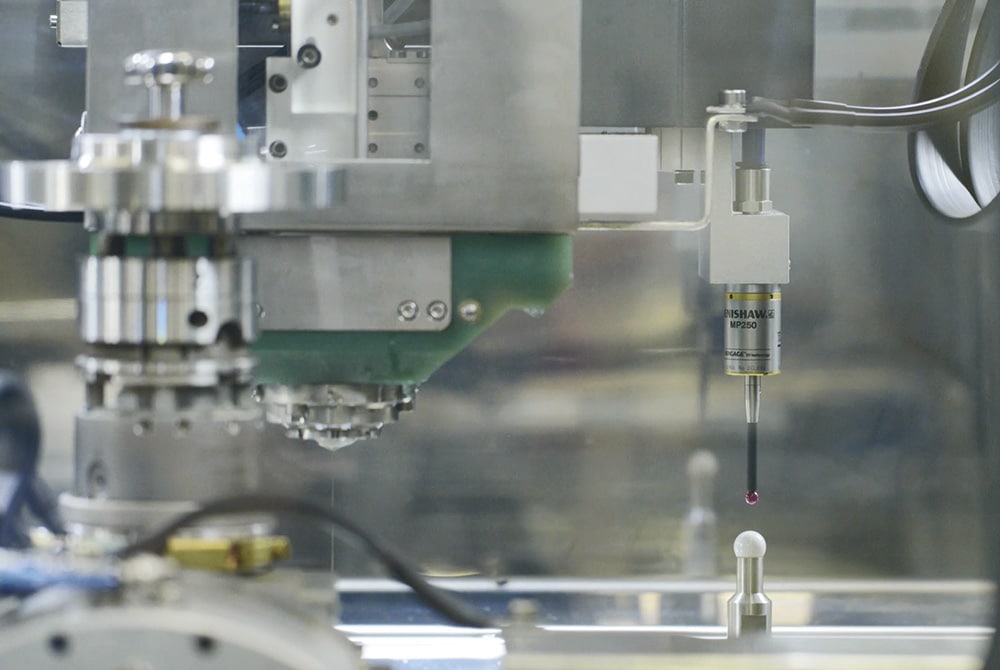

Script Programming: Smart adaptive EDM machining.

\ Script Programming: Smart adaptive EDM machining.

From our passion for EDM comes our obsession with incorporating constant improvements into our machines that optimise production processes and improve finish quality.

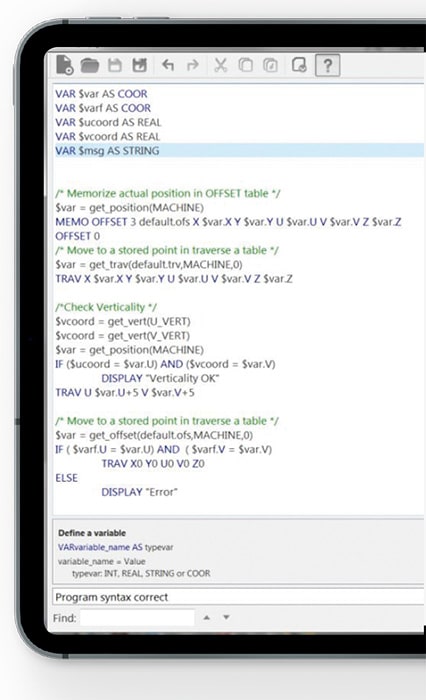

An example of this is our Script Programming tool. A high-grade programming language that allows for the creation of smart programmes. Projects can be modified during the process to react to changing conditions, thereby guaranteeing piece quality.

It is yet another of ONA’s competitive advantages, making all of our customers’ manufacturing processes more profitable.

Smart machining through dynamic programmes.

All of our models have the option of including an additional package with our Script Programming smart programme creation tool. What advantages does this provide to our customers’ production processes? Mainly improving production in terms of time and, above all, improving piece manufacturing quality. This system can check if the pieces’ values meet those demanded during the process. If they don’t, it takes proper action to correct them during the execution process.

This new adaptive machining concept is based on the ability to react to changing conditions. Script Programming benefits from the application’s knowledge and experience, and translates that into dynamic programmes capable of addressing changing conditions, rules, and variables. The more knowledge it has about the manufacturing process, the more competitive it will be. The possibilities offered by Script Programming are infinite.

None of this is possible with conventional programming, which is appropriate for pre-planned, static procedures where no changes are expected.

\ ONA Script Programming: Competitive advantages.

Advantage 01

Create personalised setup cycles.

Allowing setup operations to be carried out as defined by the user, thereby providing cycles that are adapted to each piece type.

Advantage 02

Execute actions conditioned by a series of premises.

Allowing for process programming to be modified during execution. Without this option, the piece machining instructions are defined beforehand and cannot be changed. Thanks to Script Programming, we can redefine the rules, adapting them to the process’s variable conditions during its execution. For example, if the electrode has been used 5 times (the value can be changed), we can make an electrode change. If it has been used fewer times, we can continue using the same electrode.

Advantage 03

Programming with variables:

- Allowing for strategies to be designed with variables. This way, the same programme can be used for different piece references by simply modifying some of the variable values.

- This allows the user to save information while executing the programme with a personalised work report and file with the machine’s records or log.

- The machine and user can interact during the execution process to verify specifications, or assign new values where necessary.

Advantage 04

Create personalised dialogue boxes.

Allowing a set of variables to be grouped so that they can be reused later simply by calling up a function. This way, errors are avoided and the programme size is reduced.

Advantage 05

View each user’s specific values during the programme’s execution through control variables.

\ Learn to use it with ONA ACADEMY.

The Script Programming tool is particularly suitable for companies with a large number of qualified personnel that need to design truly complex programmes, and for small companies that want to make personalised programmes with ONA’s support.

We at ONA make a complete technical manual available to our customers with full explications and practical examples. In addition, our ONA ACADEMY provides courses that are adapted to the different levels of knowledge of our customers’ personnel.