The university sector chooses Addilan to provide metal additive manufacturing to industrial sectors with a high technological component.

\ Addilan and metal Additive Technology for highly Technological Industry

An important university centre has acquired the Addilan V0.1 machine for WAAM additive manufacturing with the aim of producing large parts in different metal alloys. This will allow them to reach industries it was not possible to work with using their previous polymer technology manufacturing. A work philosophy based on proximity to the customer, along with the provision of advice throughout the process, is one of the advantages that makes Addilan stand out in comparison with the competition.

\ WAAM additive manufacturing technology allows them to create parts in different metal alloys and of larger dimensions.

\ Proximity to the customer, the provision of technological advice and the company’s expertise are the key factors that have led to the trust placed in Addilan.

The research work carried out by universities has always brought improvements to the industrial sectors. Within its approach based on continuous improvement, the university centre has acquired the Addilan V0.1 machine for WAAM additive manufacturing. Linked to sectors such as the naval and aeronautics sectors, this university carries out its research work in different areas of knowledge closely related to the environment in which it is located. The university sector is well aware that the WAAM additive manufacturing technology can optimise its production processes, allowing them to provide specialist services to industrial sectors with which they were unable to work before.ent.

Expanding horizons.

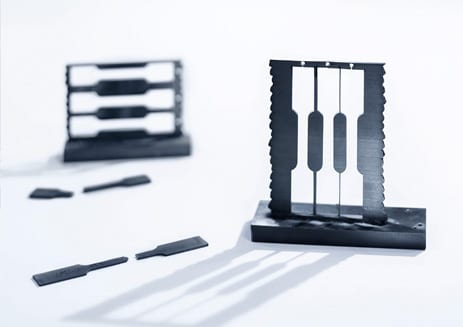

The university is currently working with polymer technology as an alternative to conventional manufacturing methods and materials. The acquisition of the Addilan machine allows them to offer an additive manufacturing system in metal with materials such as steel, titanium alloys, superalloys and aluminium alloys. In addition, with WAAM technology the part is generated at a higher speed, which allows large parts to be manufactured in a short time. Manufacturing times are therefore reduced, improving the profitability of production processes.

The opportunity to create parts in different metal alloys and of larger dimensions has allowed them to broaden their horizons and provide specialist services to industrial sectors with a high technological component where polymer technology did not meet the demanding requirements.

The multiple advantages that this first Addilan machine incorporates into their production processes has also led to them assessing the possibility of working in what will be new fields for them, such as the hybridisation of materials.

Proximity to the customer.

If you ask them why they decided to trust in Addilan for the purchase of their new machine, their response is perfectly clear: “The main difference between ADDILAN and the competition is without any doubt their proximity to the customer, the technological advice they provide and the expertise demonstrated throughout the process, always collaborating in the search for the most appropriate solution to each issue that arises.” The university notes that the outstanding advantages of the ADDILAN V0.1 additive manufacturing model include “its plasma technology, the inert atmosphere and its own process control. These have been key factors in our choice”.