MAIER uses ONA EDM for the manufacture of plastic injection moulds of the front exterior car grille for automotive components.

MAIER uses EDM for the manufacture of plastic injection moulds for cars

MAIER uses ONA EDM for the manufacture of plastic injection molds of the front exterior car grille for automotive components

Front grille of the bumper of a Jaguar XF type manufactured by MAIER

Mould for the front grille of a Mercedes model of car inside an NX6 machine belonging to MAIER

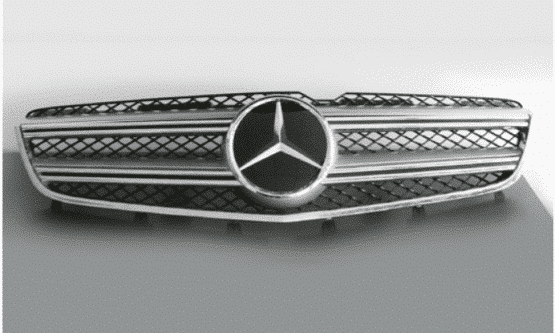

Front grille of a Mercedes model of car manufactured by MAIER

PLASTIC INJECTION MOULD FOR FRONT EXTERIOR CAR GRILLE

The cooperative MAIER is the European leader in the development and manufacture of textured automotive components for both the exterior and the interior, such as front grilles, handles, hubcaps, etc., and is supplier to the top nine car manufacturers in the world. MAIER develops and manufactures 100% of the moulds, all of them large-scale, as part of the process of obtaining the geometry and texture of the finished parts. The finish of the mould is directly related to the aesthetics of the finished piece. 80% of the form of the mould is machined by high-speed milling and 20% by EDM. According to Mr Javier Calvo (Director of the Die Management Unit at MAIER), “EDM will always be essential for the machining of slots, ribs and deep cavities. The improvements in the latest ONA models also lead to reduced machining times for work with difficult cleaning conditions, which increases accuracy and surface quality.”

MAIER has been manufacturing moulds since its inception and has accumulated 40 years of experience. The evolution that has taken place over recent years has been outstanding. Ten years ago for example, the mould for the front grille of a car involved five different groups of components and required 2,000 hours of work. Today, these types of mould are much more complex as they require 4,000 hours of work and are manufactured as a single piece. The way of using EDM has also changed, as Mr Javier Calvo explains, “We do not use large electrodes, but many small ones instead. The erosion work carried out on the mould for a front grille requires as many as 50 electrodes.”

Company:

MAIER. The company is part of the automotive division of the Mondragon Corporation, which is the largest cooperative in the world.

Employees:

1.750

Address:

Headquarters: Ajangiz – Bizkaia – Spain. MAIER has production plants in Spain, the Czech Republic and the UK. It has joint ventures in Turkey, India and Japan

Activity:

European leader in the development and manufacture of textured automotive components for both the exterior and interior, such as front grilles, handles and hubcaps.

Clients:

It is the supplier to the top nine car manufacturers in the world.

Equipment:

Die sinking EDM equipment at the production plant in Gernika (Spain): 4 ONA EDM machines

EDM for the machining of the largest turbine disc firtrees.

ONA’s WEDM technology has proven to be a match for conventional methods such as broaching and milling in terms of quality and precision

Dubral optimises the precision and quality of its cutting with ONA AV35 model

The acquisition of the ONA AV35 model has allowed the company to improve the precision in its cutting, increasing efficiency

Sermec acquires the ONA AV35 machine to strengthen its EDM machining capacity

This fleet currently includes 4 wire EDM machines (AF25, AF35, AV25 and AV35), as well as a DR2 model erosion drilling machine.

ONA EDM technology optimises the performance of the MCM production process

The acquisition of ONA’s AV25, AV35 and AV60 models has meant an increase in profitability and quality for MCM and a high level of satisfaction.

Sabacaucho to machine large moulds for elastomeric parts with the ONA IRIS8 B1L+ machine

Sabacaucho’s requirement for a machine with a high capacity for machining and repairing larger moulds led the company to contact ONA.

Tecnijusta expands its capacity to manufacture larger moulds with the ONA Iris 6 machine

Tecnijusta acquires the ONA Iris 6 model to strengthen its capabilities and improve efficiency in the EDM process.