ONA extends its range to Microholes EDM technology which enables the manufacture of the most complex pieceswith the highest precision.

Microholes EDM High level of precision for more demanding finishes.

With the acquisition of 30% of the American company AAEDM, ONA extends its range to microholes EDM technology which enables the manufacture of the most complex pieceswith the highest precision.

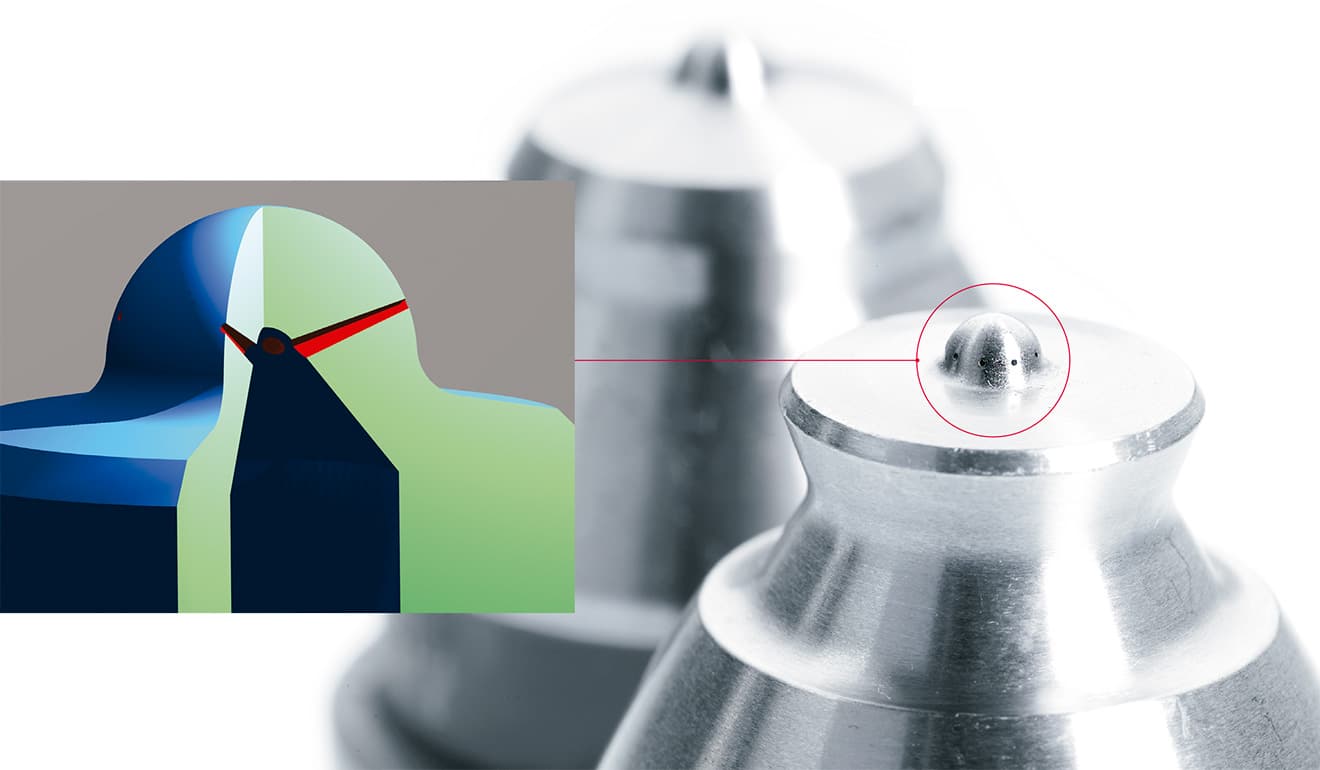

ONA has added micro hole EDM technology to its product catalogue with the MF5 machine. This machine produces pieces with holes that are 0.08mm to 4mm in diameter. Thanks to the purchase of 30% of the American company AAEDM, with a technical team accumulating over20 years’ experience, this new technology enables the manufacture of the most complex pieces with excellent precision levels. This technique is applied in such diverse fields as energy generation, aerospace, the aeronautical industry, the automotive industry (diesel fuel injectors) and the medical industry.

These machines offer multiple advantages such as very economical maintenance and a wide range of hole shapes thanks to its programmable head (conical, semi-conical and irregular). In addition, the flexibility and robustness parameters characteristic of ONA are also applied to these machines, which can be customized, and also offer numerous automation options like automatic flow tests, adapted controls, laser markers or vision systems.

For ONA, this acquisition is part of the company’s diversification strategy with a clear objective to complement traditional organic growth channels. ONA raises its business opportunities with current as well as new clients from such well-known industries as the energy industry, aerospace, the automotive industry and medicine. Similarly, this operation will help AAEDM machines access the European market.

Moreover, ONA is currently working on new proposals to adapt micro hole technology to the cooling of blades in the aeronautical sector

Strategic Role of EDM and Additive Manufacturing in Defense Advanced Manufacturing

Discover how EDM and additive manufacturing are transforming defense, boosting operational resilience, self-sufficiency, and precision in military production.

ONA IRIS-08B1L+ with 200-amp generator boosts productivity at Schlumberger

Schlumberger boosts its productivity with the new ONA IRIS-08B1L+ equipped with a 200 amp generator

EDM for the machining of the largest turbine disc firtrees.

ONA’s WEDM technology has proven to be a match for conventional methods such as broaching and milling in terms of quality and precision

Dubral optimises the precision and quality of its cutting with ONA AV35 model

The acquisition of the ONA AV35 model has allowed the company to improve the precision in its cutting, increasing efficiency

Sermec acquires the ONA AV35 machine to strengthen its EDM machining capacity

This fleet currently includes 4 wire EDM machines (AF25, AF35, AV25 and AV35), as well as a DR2 model erosion drilling machine.

ONA EDM technology optimises the performance of the MCM production process

The acquisition of ONA’s AV25, AV35 and AV60 models has meant an increase in profitability and quality for MCM and a high level of satisfaction.