PSA Peugeot Citroën in Mulhouse has 9 ONA EDM machines for the manufacture of nitrided forging dies – one of the toughest tasks that Peugeot undertakes.

EDM for manufacturing nitrided forging dies at PSA Peugeot Citroën

A total of 9 ONA machines are used by PSA Peugeot Citroen at the Peugeot production plant in Mulhouse (France) to erode nitrided forging dies – one of the toughest tasks that Peugeot undertakes. It is a good example of how die sinking EDM is used for the machining of large surface areas.

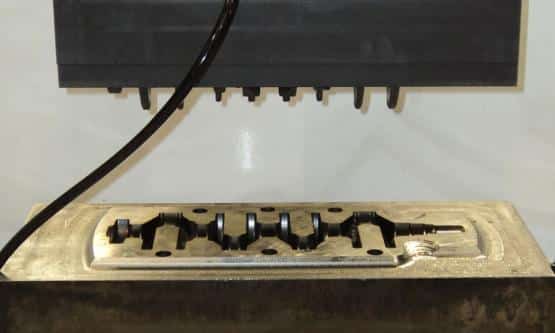

EROSION OF A NITRIDED FORGING DIE

The PSA Peugeot Citroën plant in Mulhouse has nine ONA EDM machines and is home to the main tool manufacturing centre for the PSA Peugeot Citroën group. The tool manufacturing centre, known as OCMB (Outillage Central Mécaniques et Bruts), is also responsible for providing tools to external car manufacturing clients. The main type of tools that are manufactured are moulds for the production of aluminium parts (casings, gearboxes, clutches, etc.), forging dies and trimming dies.

The Mulhouse plant produces the Peugeot 2008-2015, Citroën C4 and Citroën DS4 models exclusively for Europe.

The EDM of nitrided forging dies is one of the most demanding tasks that Peugeot undertakes with its ONA EDM machines. This type of part is a good example of how die sinking EDM is used for the machining of large surface areas.

The nitriding process can significantly increase the useful life of stamping dies used to shape forged parts. Nitriding increases surface hardness and resistance to wear with a considerable dimensional stability due to the surface of the die being enriched with nitrogen and the formation of nitrides.

Despite the benefits of nitriding, the process does not prevent the die from being damaged during use, which means that it has to be reconstructed and re-machined in order to recover the initial shape. The same die can be rebuilt several times during its useful life. EDM is regarded as the best machining solution for regenerating the die because its high level of surface hardness after the nitriding process makes the use of other machining techniques impractical. EDM is also used in the initial machining of the new die, when the surface to be machined has not yet been nitrided, since machining by milling leads to problems in the vertical faces due to the vibration which occurs in the milling cutter.

The iron nitride coating on the nitrided dies requires the use of EDM machines that are equipped with high- amperage generators. ONA die sinking machines from the NX series have the optional feature of generators of up to 400 amps. These make it possible to efficiently machine the nitrided surface, obtaining high initial volume in the roughing phase and achieving a homogeneous final roughness on large surface areas.

Company:

PSA Peugeot Citroën

- 2.9 million vehicles manufactured (2014).

- 2nd largest European manufacturer with a market share of 11.8%.

- 184,800 employees around the world.

Address:

Production plant at Mulhouse – Francia-

Activity:

Engineering, manufacturing and assembly of the Peugeot 2008, Citroën C4 and Citroën DS4 models, with an annual output of 244,000 cars (2014).

ONA EDM machines installed:

9 ONA EDM machines.

Strategic Role of EDM and Additive Manufacturing in Defense Advanced Manufacturing

Discover how EDM and additive manufacturing are transforming defense, boosting operational resilience, self-sufficiency, and precision in military production.

ONA IRIS-08B1L+ with 200-amp generator boosts productivity at Schlumberger

Schlumberger boosts its productivity with the new ONA IRIS-08B1L+ equipped with a 200 amp generator

EDM for the machining of the largest turbine disc firtrees.

ONA’s WEDM technology has proven to be a match for conventional methods such as broaching and milling in terms of quality and precision

Dubral optimises the precision and quality of its cutting with ONA AV35 model

The acquisition of the ONA AV35 model has allowed the company to improve the precision in its cutting, increasing efficiency

Sermec acquires the ONA AV35 machine to strengthen its EDM machining capacity

This fleet currently includes 4 wire EDM machines (AF25, AF35, AV25 and AV35), as well as a DR2 model erosion drilling machine.

ONA EDM technology optimises the performance of the MCM production process

The acquisition of ONA’s AV25, AV35 and AV60 models has meant an increase in profitability and quality for MCM and a high level of satisfaction.