ONA IRIS-08B1L+ with 200-amp generator boosts productivity at Schlumberger

ONA IRIS-08B1L+ with 200-amp generator boosts productivity at Schlumberger

In 2015, Schlumberger, a world leader in oilfield services and a Fortune Global 500 company, incorporated an ONA A0 NX7 into its operations. That acquisition marked the beginning of a Relationship based on the precision, reliability, and performance of ONA’s EDM technology. Nine years later, in 2024, the company decided to renew its confidence with the purchase of an ONA IRIS-08B1L+ 200 amp, a latest-generation model that has optimized its component manufacturing process for the oil industry.

A Machining Challenge in Hard Materials and Inaccessible Areas

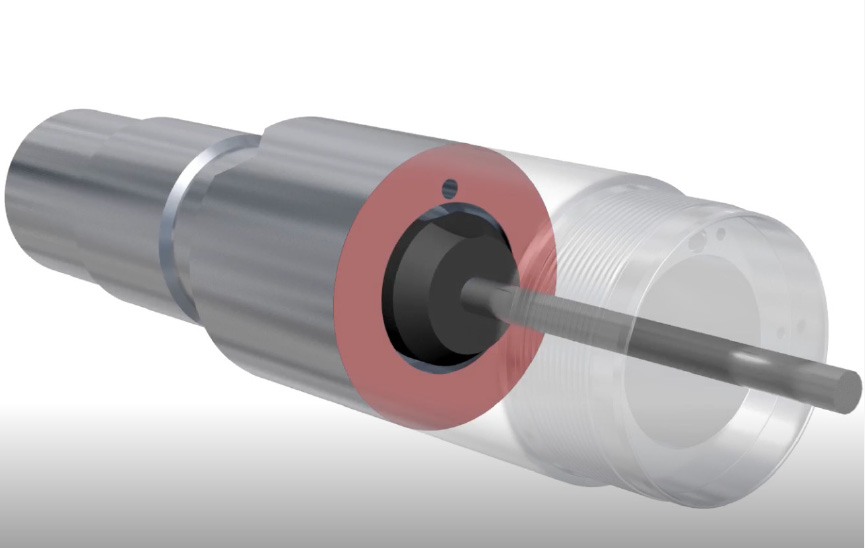

Schlumberger operates in extremely demanding environments where every component must meet very strict tolerances. One of its key processes involves making indentations in large, highhardness tubes intended for drilling operations.

These tubes must maintain their geometric integrity under very severe pressure and load conditions, which makes their machining a critical challenge.

The problem lies not only in the hardness of the material but also in the limited accessibility of the area to be eroded. With traditional technologies like milling, tooling costs, Access complexity, and machining times skyrocket. For this reason, Electrical Discharge Machining (EDM) positioned itself as the most effective alternative. EDM allows for work without mechanical contact, maintains dimensional stability, and offers the necessary precision even in internal or very narrow geometries.

ONA IRIS-08B1L+ 200 amp, ONA’s Technological Answer

The incorporation of the ONA IRIS-08B1L+ 200 amp represents a qualitative leap for Schlumberger. Its differentiating element is the 200 amp generator, unique in the EDM sector, designed to maximize material removal capacity. This additional power translates into:

- Faster machining cycles, even in extremely hard materials.

- Greater process stability, which is key to ensuring repeatability.

- A notable increase in productivity, reducing waiting times and improving the plant’s overall capacity.

Furthermore, this model features optimal dimensions for working with large tubes, which facilitates handling and allows for addressing higher-volume applications without physical restrictions.

Results Obtained by Schlumberger

Since its installation, the IRIS-08B1L+ 200 amp has generated clear and measurable improvements:

- Significant reduction in erosion time, thanks to the power of the generator.

- Greater geometric consistency, even in hard-toaccess internal indentations.

- Fluid integration into the production line, facilitated by the automation options and the equipment’s ergonomics.

Automation and Efficiency with Dual-Head Configurations

In addition to the model acquired by Schlumberger, ONA has advanced dual-head configurations that represent a significant evolution in terms of productivity and efficiency. The dual head allows for:

- Twice as many tubes to be eroded in the same time, doubling productivity with the same number of operators.

- The possibility of placing multiple tubes on each head, maximizing the occupancy of the work tank.

- Automation that enables continuous and prolonged processes, ideal for 24/7 shifts or intensive production.

In short, the incorporation of the ONA IRIS-08B1L+ 200 amp confirms Schlumberger’s commitment to EDM technologies capable of responding to the most demanding challenges in the oil sector.

The exclusive power of the generator, the precision obtained in extremely hard materials, and the possibilities for automation position this model as a key element for increasing productivity.

This is reinforced by the experience accumulated since 2015, which strengthens mutual trust between both companies. With this new investment, Schlumberger strengthens its industrial leadership, and ONA EDM consolidates its position as a technological benchmark in critical, high-added-value applications.

Company:

Schlumberger Limited

Employees:

More than 95,000 employees in 85 countries

Facilities

Headquarters in Houston, Paris, London, and The Hague

Sectors:

- Energy and Petroleum – Advanced services for oilfields, drilling, formation evaluation, and well completion

- Gas and Underground Exploration – Solutions for geophysical analysis, logging, reservoir management, and production optimization

- Water and Environment – Groundwater extraction services and technologies applied to sustainable subsurface management

- Carbon Capture and Storage (CCS) – Technologies and services for CO₂ capture, injection, and monitoring projects

- Energy Technology and Software – Development of digital platforms, data analysis, and specialized software for the subsurface industry

Equipment:

- ONA A0 NX7, ONA IRIS-08B1L+ 200

ONA IRIS-08B1L+ with 200-amp generator boosts productivity at Schlumberger

The acquisition of the ONA AV35 model has allowed the company to improve the precision in its cutting, increasing efficiency

EDM for the machining of the largest turbine disc firtrees.

ONA’s WEDM technology has proven to be a match for conventional methods such as broaching and milling in terms of quality and precision

Dubral optimises the precision and quality of its cutting with ONA AV35 model

The acquisition of the ONA AV35 model has allowed the company to improve the precision in its cutting, increasing efficiency

Sermec acquires the ONA AV35 machine to strengthen its EDM machining capacity

This fleet currently includes 4 wire EDM machines (AF25, AF35, AV25 and AV35), as well as a DR2 model erosion drilling machine.

ONA EDM technology optimises the performance of the MCM production process

The acquisition of ONA’s AV25, AV35 and AV60 models has meant an increase in profitability and quality for MCM and a high level of satisfaction.

Sabacaucho to machine large moulds for elastomeric parts with the ONA IRIS8 B1L+ machine

Sabacaucho’s requirement for a machine with a high capacity for machining and repairing larger moulds led the company to contact ONA.