ONA EDM leads the era of intelligent automation

ONA EDM leads the era of intelligent automation

Automation is revolutionising the manufacturing industry by incorporating advanced technologies such as artificial intelligence, robotics and data analytics. These technologies enable companies to become more efficient, reduce costs and improve the quality of their products. At the same time, workers are freed from repetitive tasks, allowing them to focus on value-adding tasks.

Automation also improves workplace safety and fosters innovation by speeding up design and manufacturing, enabling rapid adaptation to market demands. In a competitive environment, automation is crucial. At ONA EDM, we have been implementing automation solutions for our customers for years, ensuring that they are leaders in their industry.

Lean Manufacturing and Six Sigma

The incorporation of Lean Six Sigma methodologies has been fundamental in the optimisation of industrial processes, especially in sectors such as aerospace, where the equirements for precision and quality are more demanding. Lean Manufacturing focuses on minimising waste and maximising efficiency by identifying and eliminating activities that do not add value to the production process. Thisis particularly important in the manufacture of complex components, where even small deviations can have significant consequences. By applying Lean Manufacturing and Six Sigma in the aerospace industry, more efficient and high-quality production is achieved. The methodologies allow companies to optimise their workflows, reduce costs and improve the quality of the final product.

Automation in ONA LEAN: ONA IRIS 4 LEAN and ONA IRIS 6 LEAN

These machines retain the advanced features of the IRIS range, but with a more compact design. The relocation of the generator to the rear allows a reduced size, leaving only the work tank and control screen at the front. This design aims to optimise working space and improve efficiency and profitability through automation and resource optimisation.

The ONA IRIS LEAN models include digital tools to enhance the user experience, a powerful 3D graphics engine and a large touchscreen. In addition, their configurable digital generator allows complete customisation. Automation is a key feature of these models, facilitating the transfer and downloading of data, external connections, security, integration with other software and remote process management. Leading OEMs in the turbine sector have chosen ONA EDM and its LEAN models because they take up less space without compromising quality and functionality.

Automation solutions at ONA EDM

ONA optimises its manufacturing processes through various automation solutions, including the following innovations:

- Rotary changers: These devices, integrated into ONA IRIS machines, allow capacity to be increased to up to 80 electrodes, significantly improving operational efficiency.

- Multi-electrode Robot: This compact robot handles workpieces andelectrodes on fixed or rise and fall tank machines, with a load capacity of up to 30 kg and an X-axis travel of 1200 mm. Its implementation allows for more efficient and precise operation.

- Multi-machine projects: Robots with automatic arms feed machines, enabling continuous operation throughout the night and increasing productivity by up to 400%. They ensuregreater accuracy and efficiency, optimising resources and reducing downtime.

These automation solutions enable ONA to offer high quality and efficient production, adapting to the specific needs of each customer and ensuring that manufacturing processes are as efficient and costeffective as possible.

Maximum Automation, Maximum Productivity

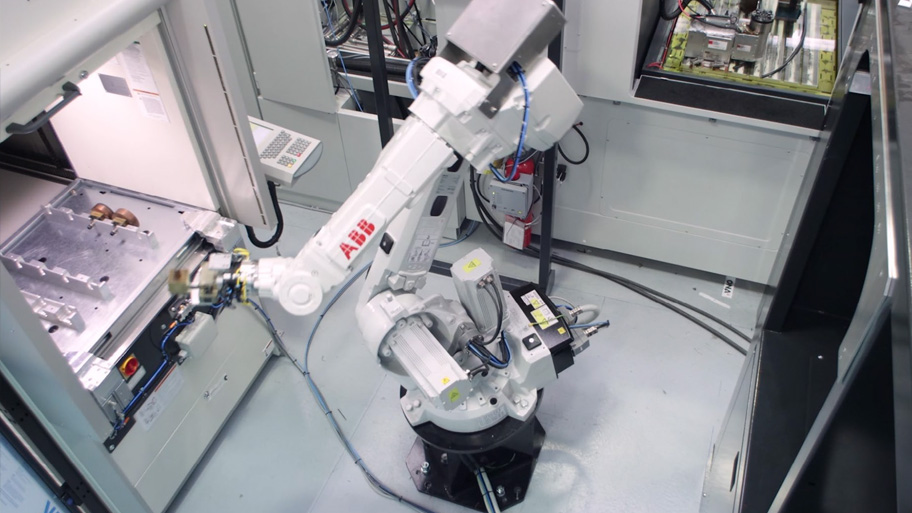

ONA EDM’s latest breakthrough in automation is the development of a complete robotic manufacturing cell in collaboration with ARMIN, the company responsible for its control system. This automated cell integrates the ONA IRIS 4 LEAN model and is specifically designed to maximize efficiency and productivity for one of the world’s leading turbine OEM’s.

The goal of the robotic cell is to ensure repeatability, provide autonomy and improve process control. The main components of the manufacturing cell include:

- Booth for electrode and part loading by the operator

- Electrode and part store (with capacity for 135 electrodes and 12 pallets of parts)

- Robot ABB

The complete cell cycle includes the following stages, which is repeated for each electrode:

- Loading of the part into the machine

- Setup (SETUP) of the part and the sphere (placed on the ONA bed)

- Electrode loading

- Three-dimensional correction of the electrode-

- Erosion on the part.