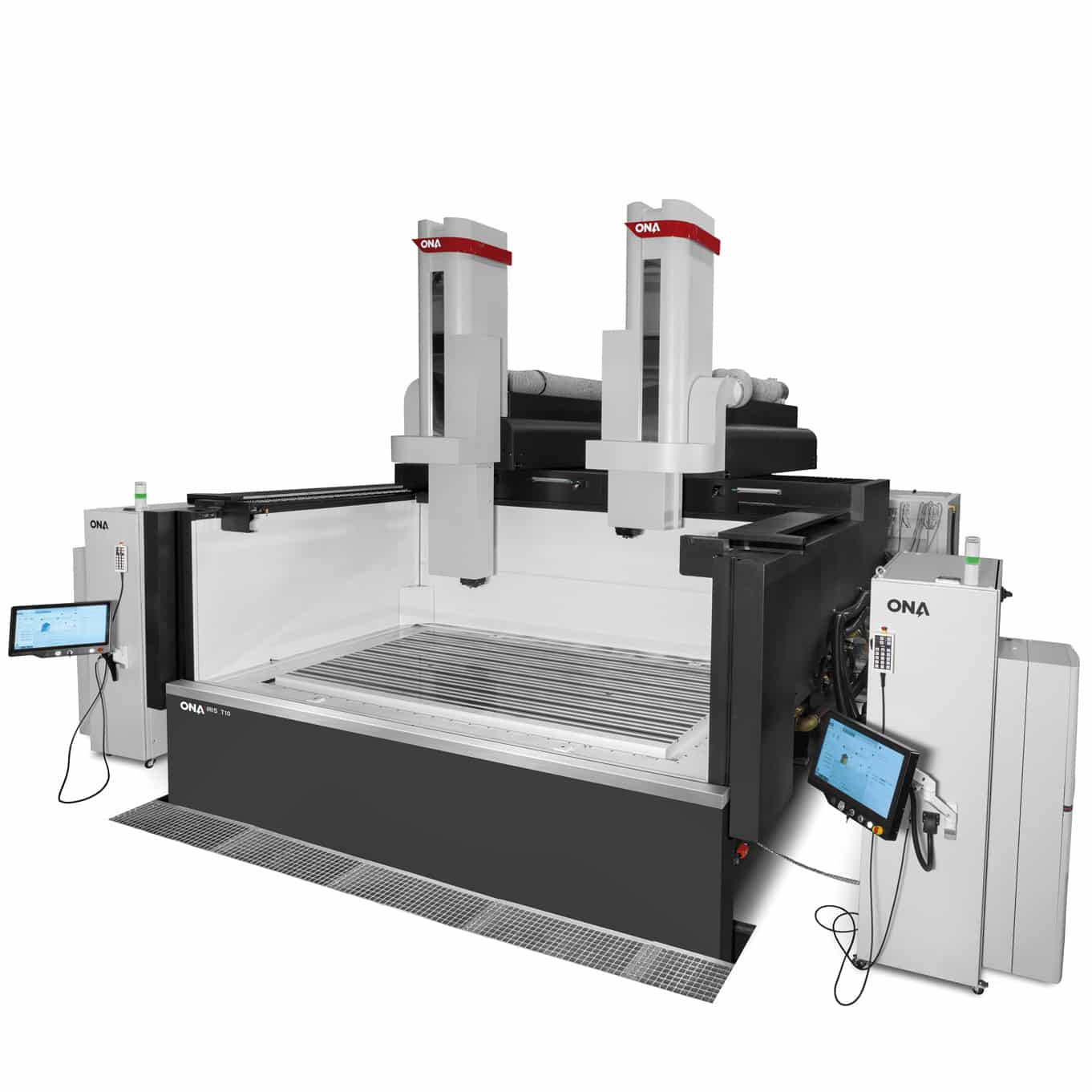

\ DOUBLE HEAD DIE – SINKING EDM MACHINES ONA IRIS T10

ONA IRIS T10 Specifications

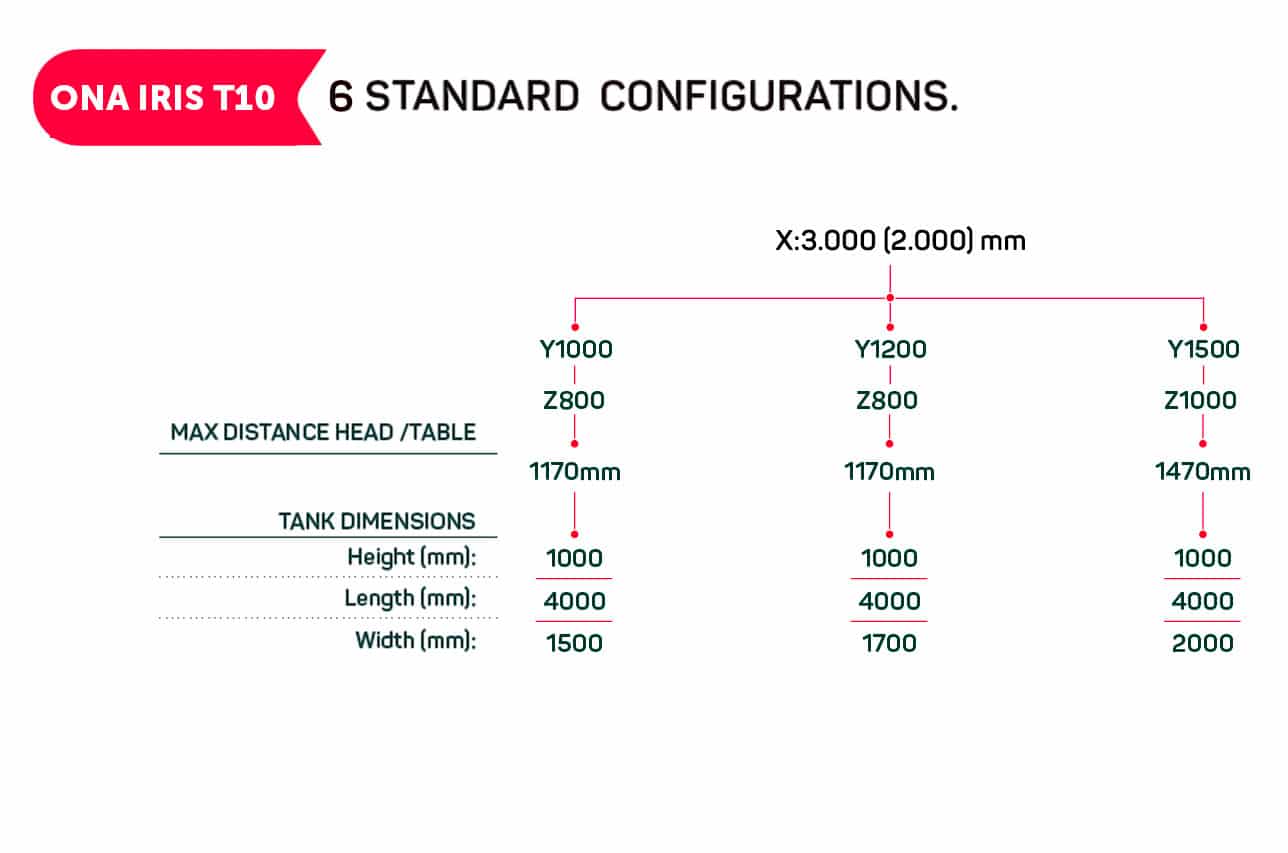

| X-axis travel (individual) | 3.000(2.000) mm | 118.11 in | |

| Y-axis travel | 1.000/1.500 mm | 39.37 / 59.05 in | |

| Z-axis travel | 800/1000 mm | 31.50 / 39.37 in | |

| Max. distance between table and head | 1.200 mm | 47.24 in | |

| Worktank internal dimensions | Length | 4.000 mm | 157.48 in |

| Width | 2.000 mm | 78.74 in | |

| Height | 1250 mm | 49.21 in | |

| Work table dimension | 3.200 x 1600 mm | 125.98 x 62.99 in | |

| Allowable weight on the table | 25.000 kg | 55116 Ibs | |

| Type of work tank | Abatible | Drop door | |

| Maximum electrode weight | 300 kg | 440 Ibs | |

| Intensity of the generator | 100|200|400 A | 100|200|400 A | |

Benefits of ONA IRIS Technology

- Reduction of erosion time of up to 50%.

- Greater efficiency with up to 200% in productivity.

- Highly rigid mechanical structure constructed of stabilized fine grained cast iron blended with graphite that allows work pieces up to 25.000 kg.

- A reinforced C axis affording stability in erosion with electrodes that have high moments of inertia (aprox. 12,000 kg/ cm2).

- Unique technological innovation. Generator 30% more powerful than the rest of the market capable of reaching up to 800 A in intensity.

- ONA IRIS machines include a very powerful control with up to 8 simmultaeously interpolating axes and volumetric compensation in the entire work area.

CASE STUDIES

ONA implements EDM machines for Volkswagen Autoeuropa

Volkswagen Autoeuropa purchases two ONA EDM machines: ONA AV35 and ONA QX4 for its press and part stamping area

EDM for the manufacture of trimming dies at PSA Peugeot Citroën

PSA Peugeot Citroën in his plant in Mulhouse has nine wire EDM machines of ONA for the manufacture of trimming dies

TESTIMONIALS

\ TESTIMONIALS

“We chose ONA because of its high-quality equipment, its excellent services, and the good supplier/customer relationship it offers. We always recommend ONA“ SIMOLDES GROUP (PT)

“We chose ONA because they are leaders in large machines, AV130 is the largest wire-cut EDM on the market. Moreover, it is so reliable that it works unsupervised every day of the week, and it maintains its high cutting speed.” STICKEL (Alemania)

“We have found in ONA a solution provider partner with values similar to ours. Thanks to their technical capacity and knowledge, we can respond to the demands of clients like Safran.” HOURAT (FR)

“Acquiring a double head ONA TQX10 and 2 robot changers with 132 positions will ensure superior working times and quality. An investment designed for our future. This is our tomorrow.” CONCOURS MOLD (USA)

“We chose ONA because of its high-quality equipment, its excellent services, and the good supplier/customer relationship it offers. We always recommend ONA“ SIMOLDES GROUP (PT)

“We chose ONA because of its high-quality equipment, its excellent services, and the good supplier/customer relationship it offers. We always recommend ONA“ SIMOLDES GROUP (PT) “We chose ONA because they are leaders in large machines, AV130 is the largest wire-cut EDM on the market. Moreover, it is so reliable that it works unsupervised every day of the week, and it maintains its high cutting speed.” STICKEL (Alemania)

“We chose ONA because they are leaders in large machines, AV130 is the largest wire-cut EDM on the market. Moreover, it is so reliable that it works unsupervised every day of the week, and it maintains its high cutting speed.” STICKEL (Alemania) “We have found in ONA a solution provider partner with values similar to ours. Thanks to their technical capacity and knowledge, we can respond to the demands of clients like Safran.” HOURAT (FR)

“We have found in ONA a solution provider partner with values similar to ours. Thanks to their technical capacity and knowledge, we can respond to the demands of clients like Safran.” HOURAT (FR) “Acquiring a double head ONA TQX10 and 2 robot changers with 132 positions will ensure superior working times and quality. An investment designed for our future. This is our tomorrow.” CONCOURS MOLD (USA)

“Acquiring a double head ONA TQX10 and 2 robot changers with 132 positions will ensure superior working times and quality. An investment designed for our future. This is our tomorrow.” CONCOURS MOLD (USA)